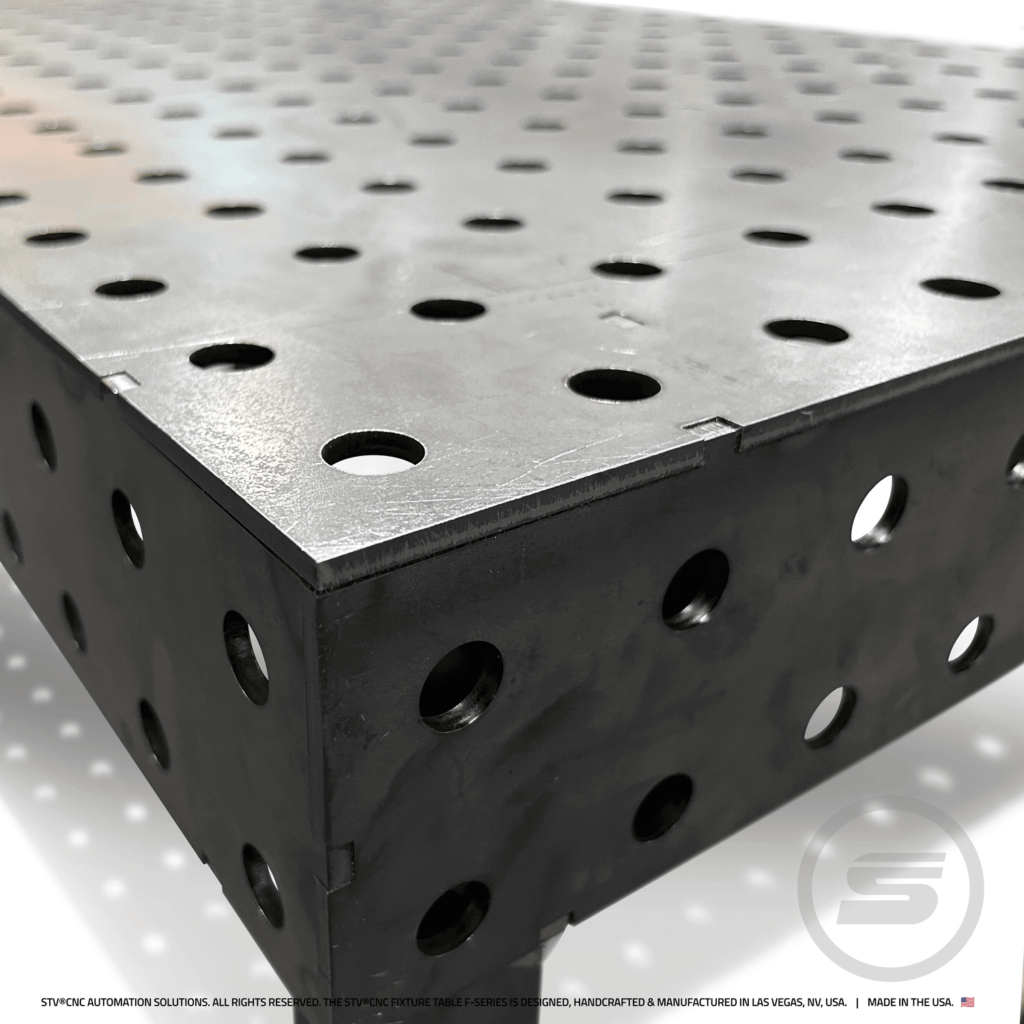

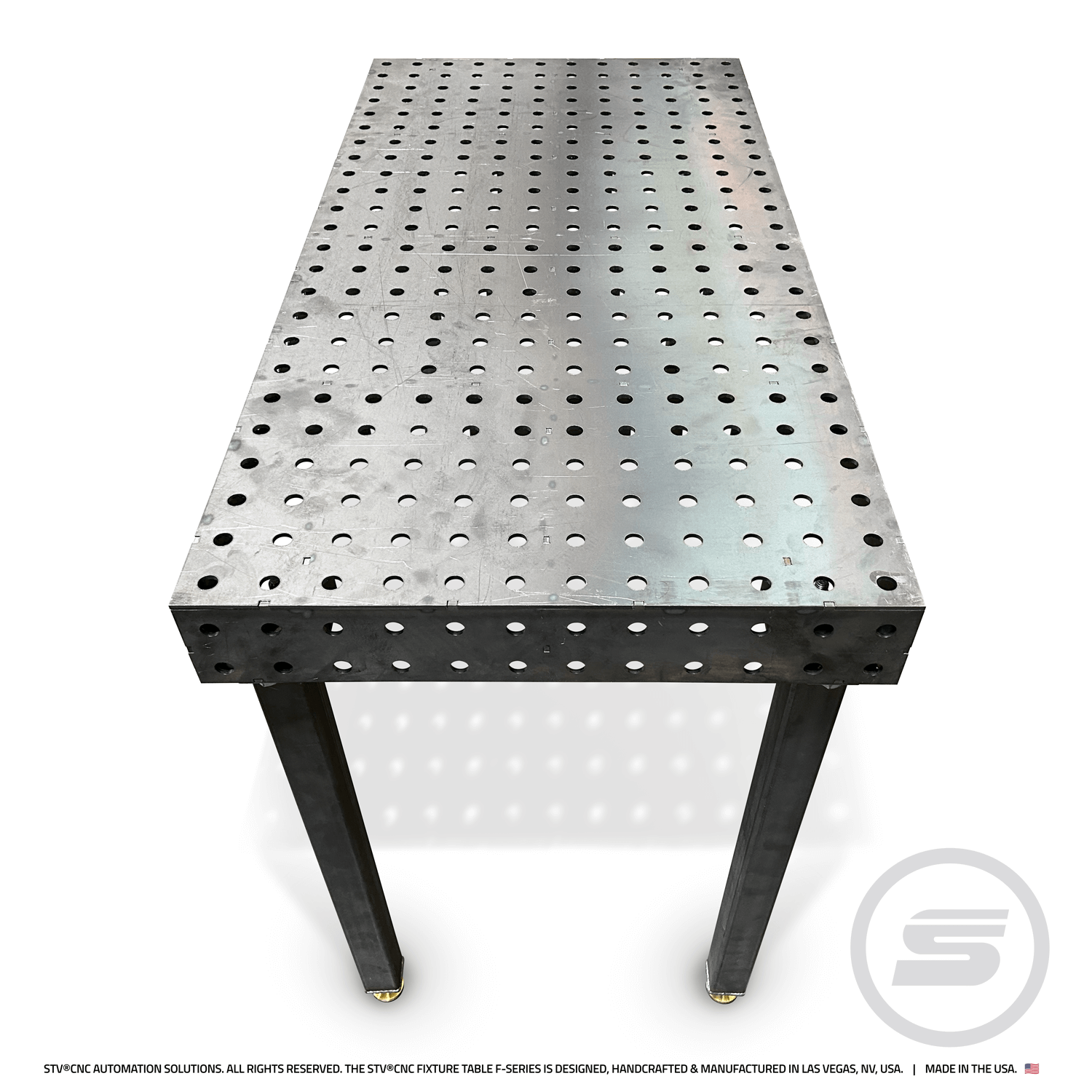

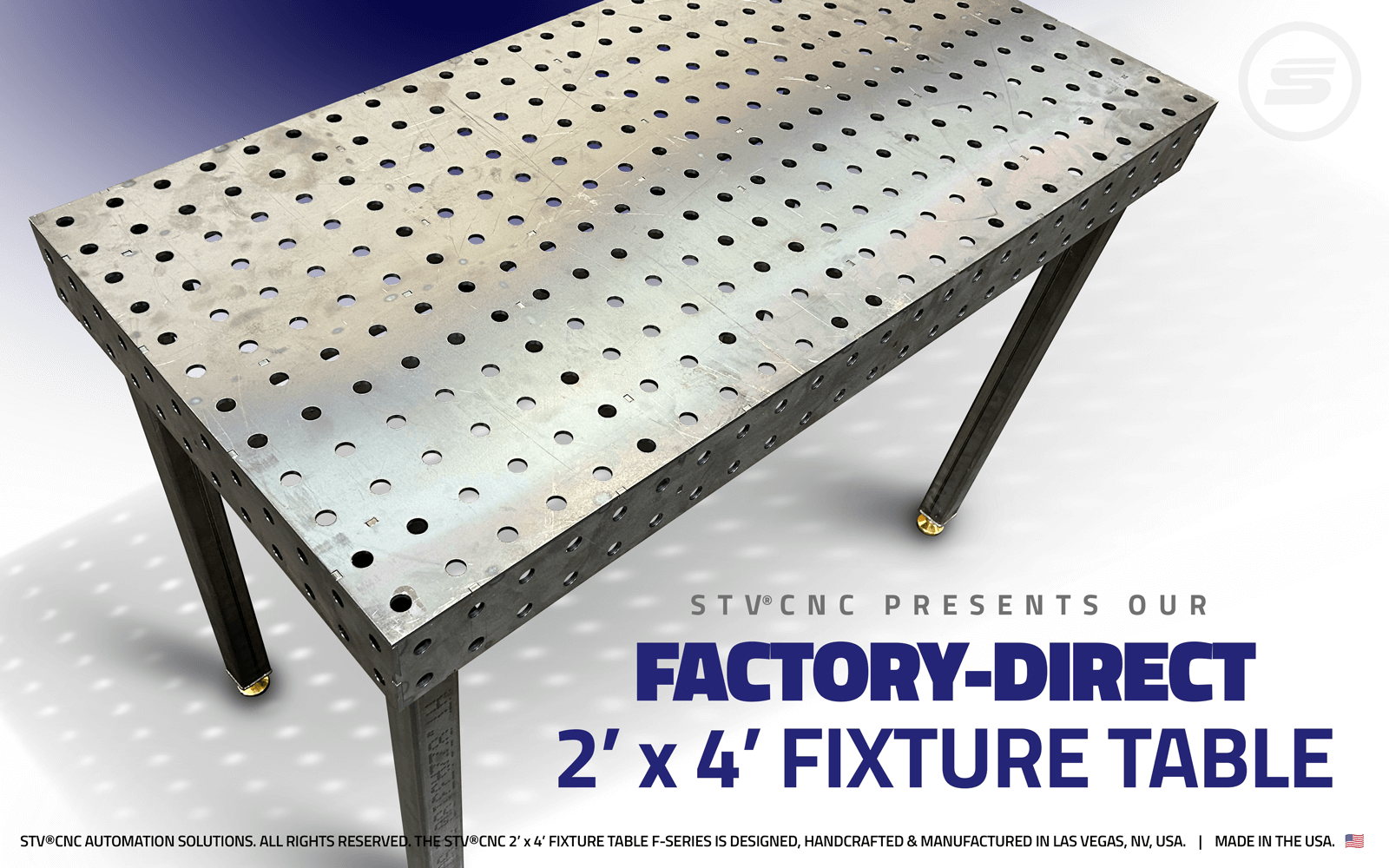

TABLE (1/4" THICK)

- Assembled Weld-Ready Table Top ≈150 lbs

- 48” (L) x 24” (W) x 36” (H)

- Top Surface Area: 8 square feet

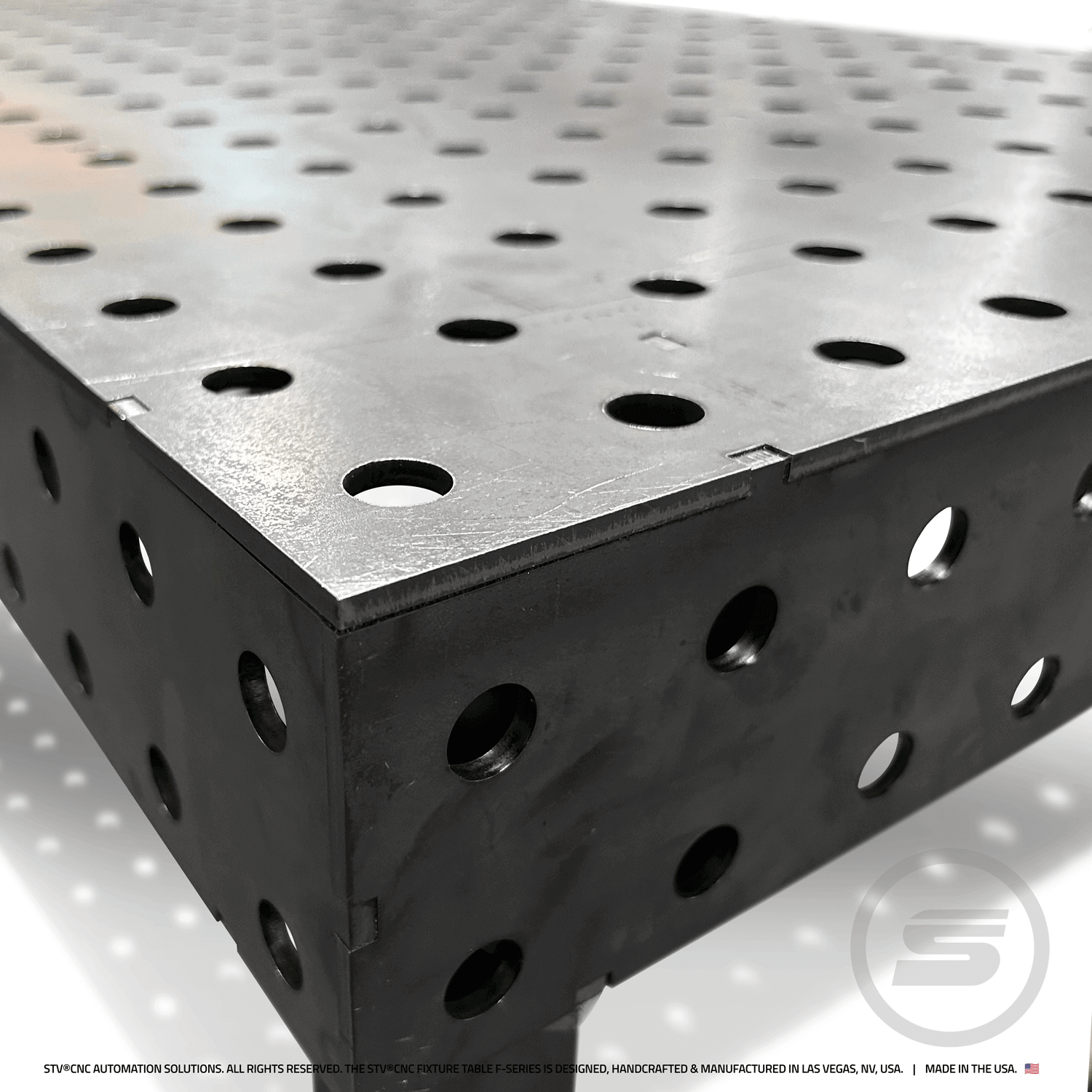

- Welded Japanese Finger Joint & Bracing

- Flat edge corners/sides & square table

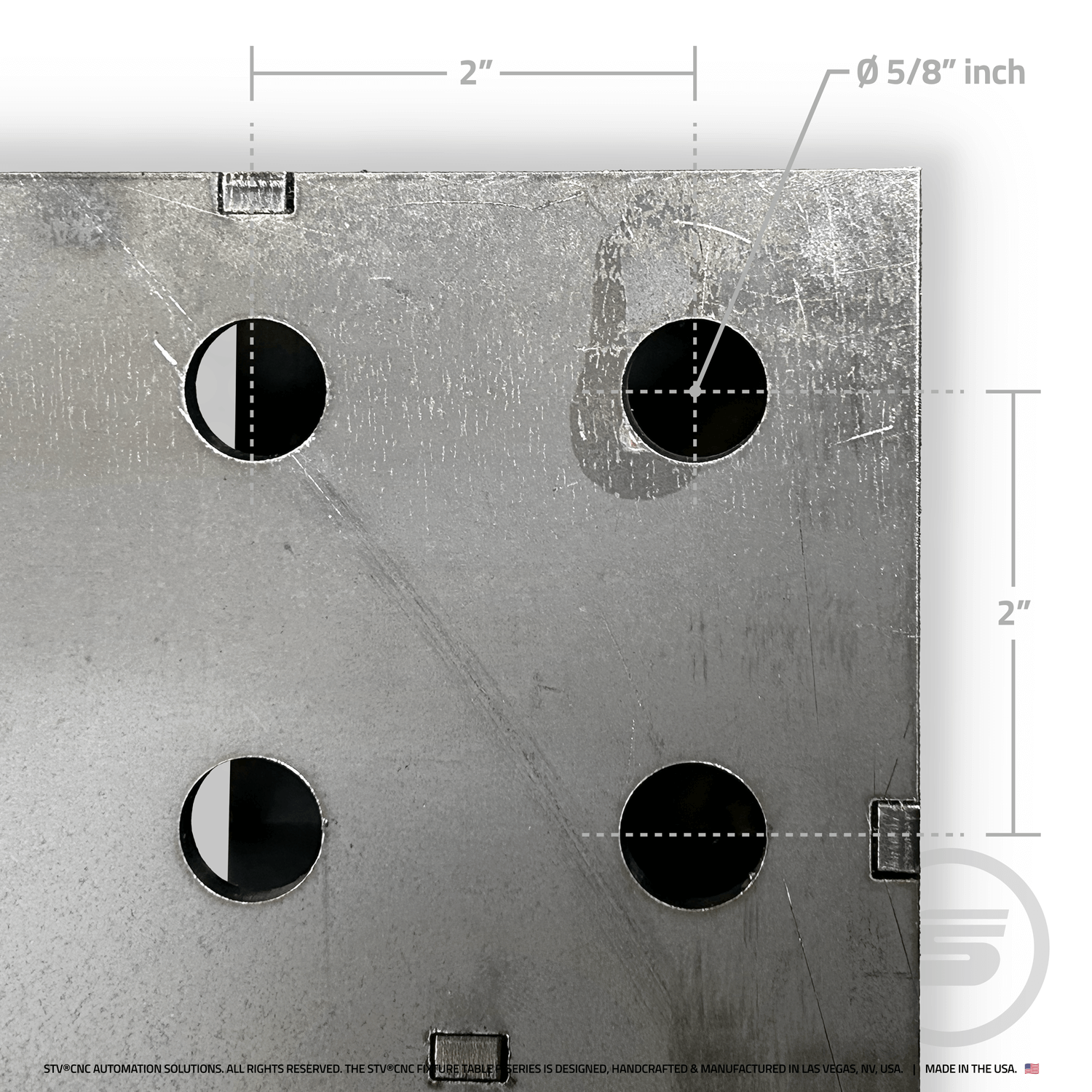

432 HOLES

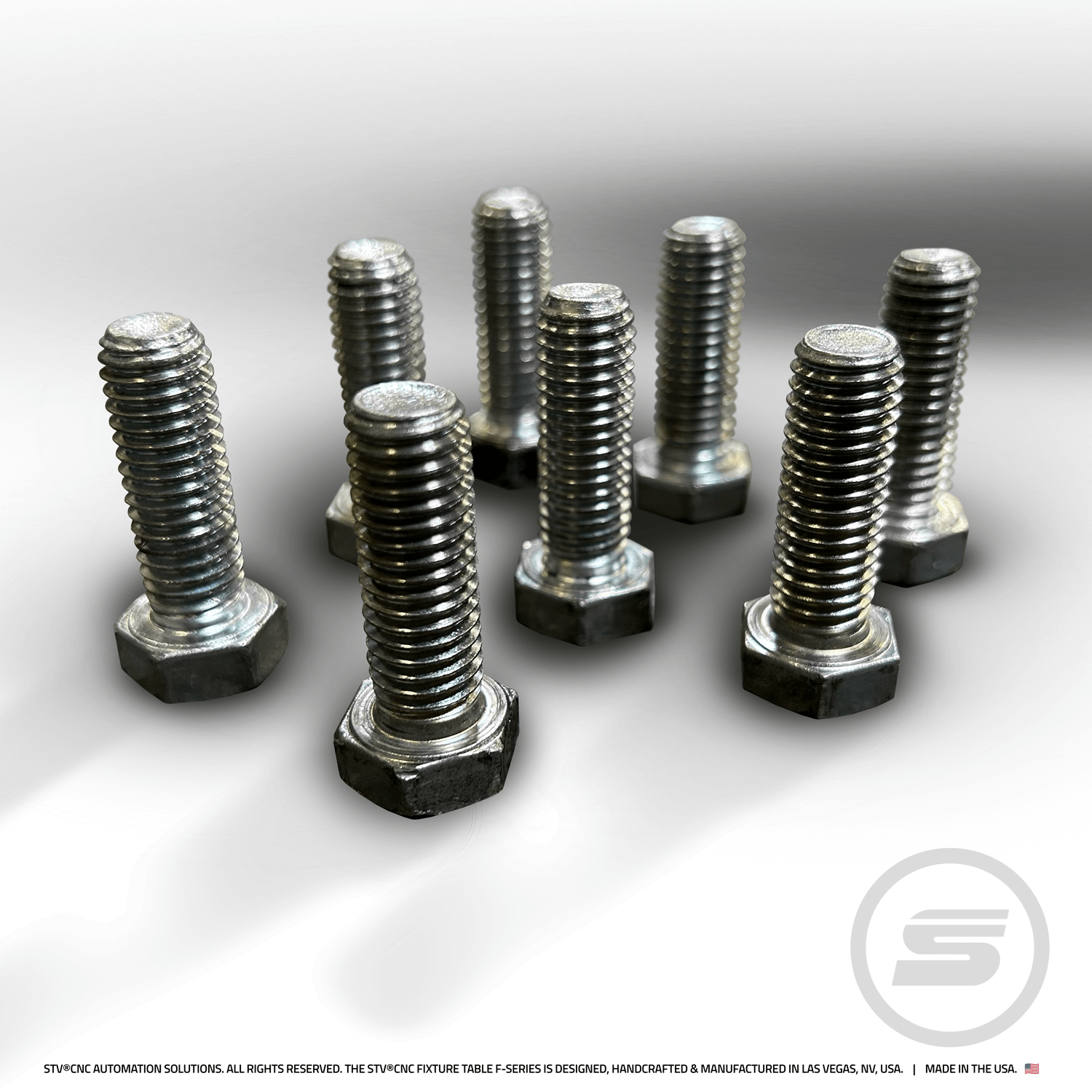

- Hole Diameter: 5/8” inch holes

- Hole Distance: 2” inch (center to center)

- 432 mounting holes for more tooling

- Smooth, non-threaded bore holes

- Easy clean, no grime

ADDITIONAL

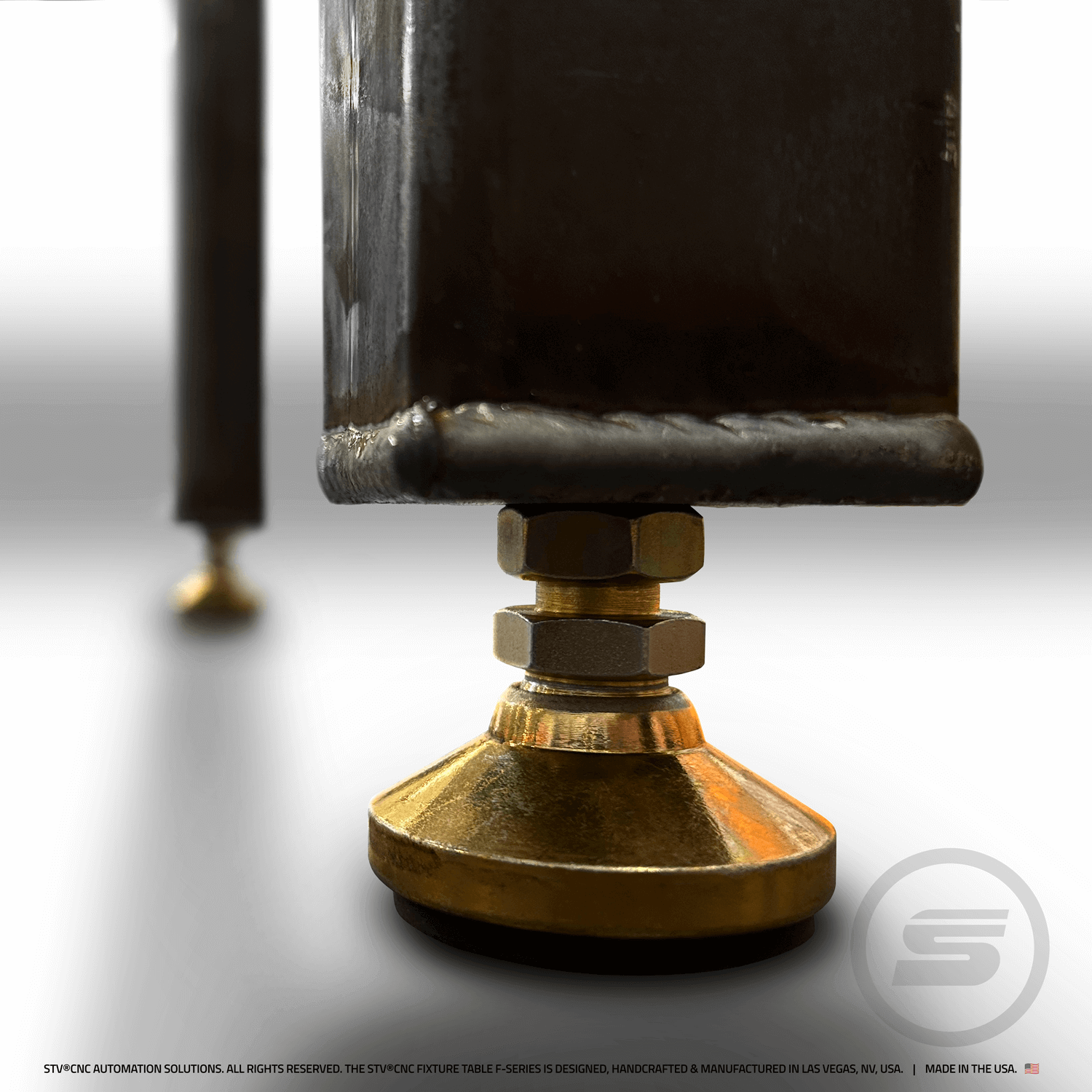

- 2” Tube 1/8" wall legs (Assembly Required)

- Leveling Feet (Assembly Required)

- Easy to transport & move

- Modular size for easy reach of tools

- Manufacturer's 1 Year Warranty

ONLINE ORDERS SHIP GROUND. FOR LARGE ORDERS, CALL US 1-888-701-7101, AS WE CAN OFFER LTL SHIPPING OPTIONS.

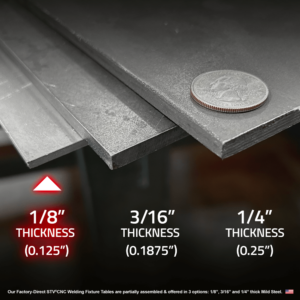

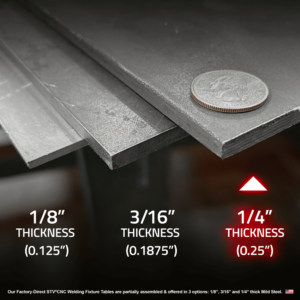

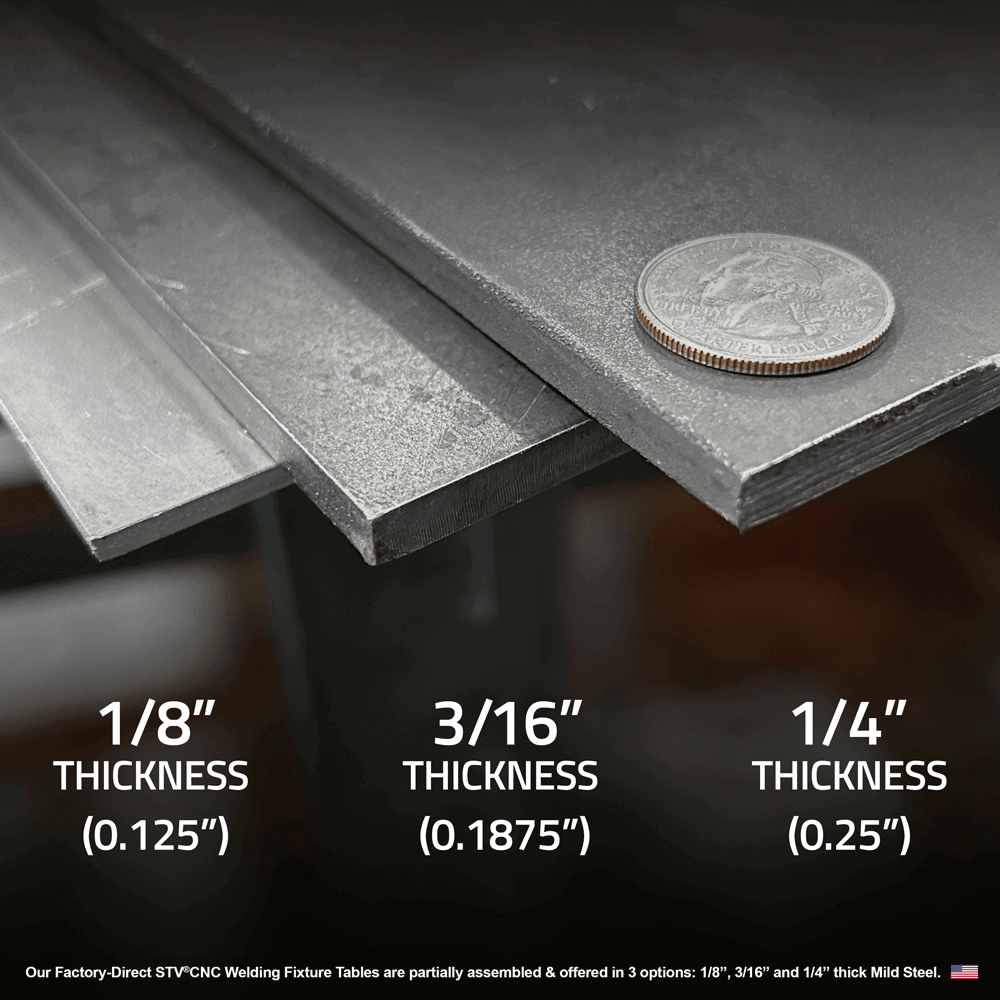

IMPORTANT: These Welding Tables are a fabricator’s modular base to begin modding. The laser cut parts are strengthened in japanese-like, minimal finger joint edging, assembled, welded together with inner mortise-tenon bracing supports and are shipped raw, unpainted with markings/scratches and possibly show minimal if any signs of corrosion. The Tubular Legs and Leveling feet are the only items that require assembly for your setup. Ready for any line of modifications. Options are available in a Hobby 1/8″ inch thickness, Light Industrial 3/16″ inch thickness and in a Heavy-Duty 1/4″ inch thickness. Please be advised: Hobby 1/8″ inch thickness is NOT recommended for Environments that handle Heavier Materials.

STV®CNC AUTOMATION SOLUTIONS. ALL RIGHTS RESERVED. THE STV®CNC FIXTURE TABLE F-SERIES IS DESIGNED, HANDCRAFTED & MANUFACTURED IN LAS VEGAS, NV, USA. | MADE IN THE USA.

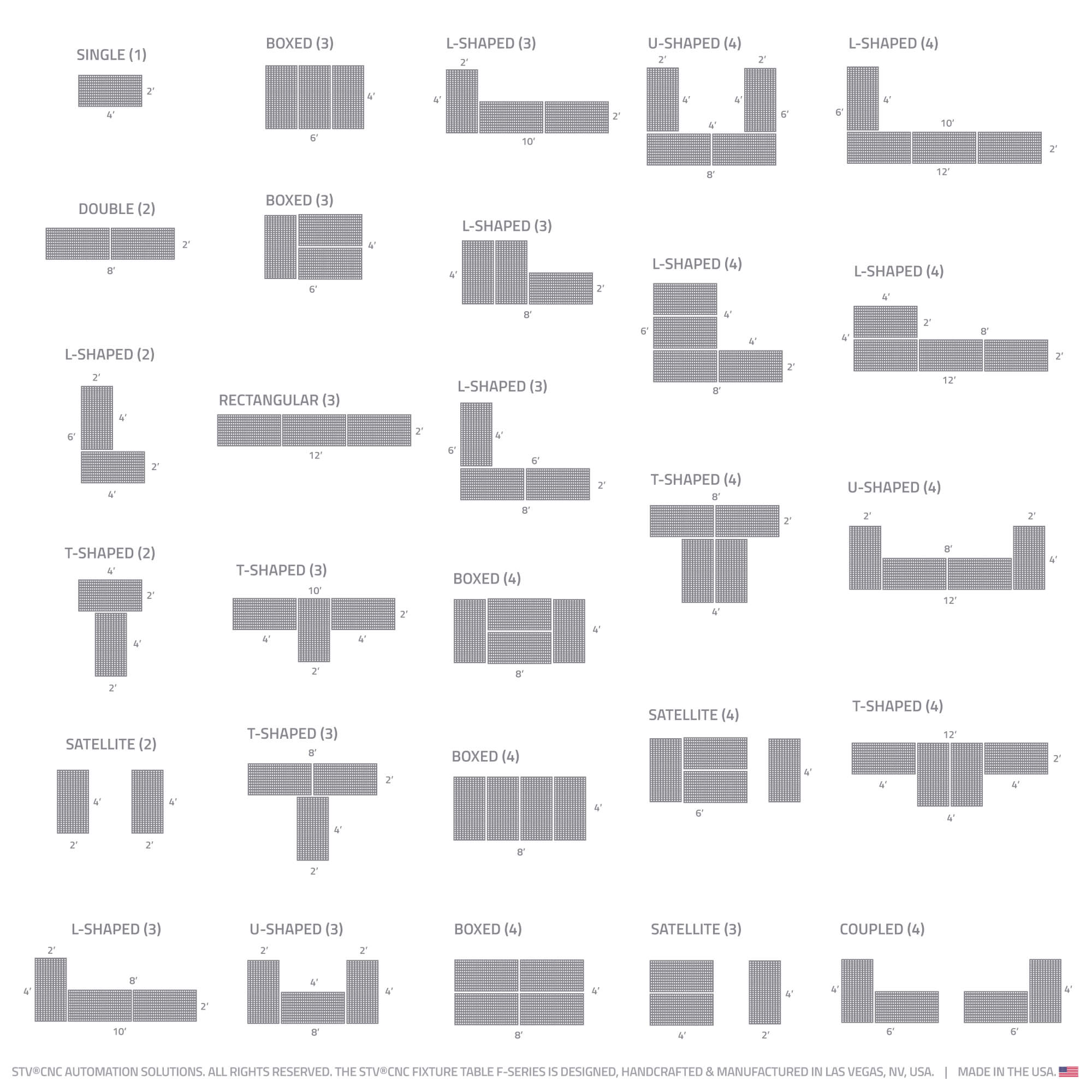

STV®CNC Welded Fab Table thickness options, Tap the Tab Titles to read more:

- HOBBY 1/8" inch

- LIGHT INDUSTRIAL 3/16" inch

- HEAVY-DUTY 1/4" inch

HOBBY LEVEL – 1/8″ INCH THICK. Introducing the ideal welding fixture table for hobbyists, the Factory-Direct 1/8″ inch thick welding table. Measuring a convenient 2′ x 4′, this sturdy fixture table is the perfect companion for your hobby-level welding projects. Crafted from raw steel and left unpainted, it’s designed to withstand the rigors of welding while providing you with a reliable and durable work surface. With minimal assembly required—just attach the legs and leveling feet—you can quickly get to work on your projects.

HOBBY LEVEL – 1/8″ INCH THICK. Introducing the ideal welding fixture table for hobbyists, the Factory-Direct 1/8″ inch thick welding table. Measuring a convenient 2′ x 4′, this sturdy fixture table is the perfect companion for your hobby-level welding projects. Crafted from raw steel and left unpainted, it’s designed to withstand the rigors of welding while providing you with a reliable and durable work surface. With minimal assembly required—just attach the legs and leveling feet—you can quickly get to work on your projects.

One of the key benefits of this table is its versatility. The 5/8″ inch hole spacing allows you to easily secure a variety of materials and workpieces in place, making intricate welding jobs a breeze. Its compact size ensures it fits comfortably in your workshop, maximizing your workspace efficiency. Plus, the affordability of this table makes it an excellent investment for hobbyists.

However, it’s important to note that this table is not recommended for heavier material-based projects. For those seeking to work with thicker materials, a more robust table may be necessary. As for hobby-related modifications, consider adding dedicated tool holders, magnetic trays, or even a vise to further enhance your welding setup. With the Factory-Direct 1/8″ inch welding table in your workshop, you’ll have the foundation you need to take your hobby to the next level.

CLICK HERE TO VIEW 1/8″ THICK FAB TABLES & OPTIONS

LIGHT INDUSTRIAL RATED – 3/16″ INCH THICK. Introducing the robust and reliable Factory-Direct 3/16″ inch thick welding table, designed to elevate your welding experience beyond hobby-level projects. With its sturdy build and impressive 2′ x 4′ dimensions, this welding table is tailored for light industrial projects, offering a rigid base that’s perfect for clamping, building jigs, and even serving as a production line base platform. Crafted from raw steel and left unpainted, this table requires only leg and leveling feet assembly, providing you with a durable, unperturbed workspace.

LIGHT INDUSTRIAL RATED – 3/16″ INCH THICK. Introducing the robust and reliable Factory-Direct 3/16″ inch thick welding table, designed to elevate your welding experience beyond hobby-level projects. With its sturdy build and impressive 2′ x 4′ dimensions, this welding table is tailored for light industrial projects, offering a rigid base that’s perfect for clamping, building jigs, and even serving as a production line base platform. Crafted from raw steel and left unpainted, this table requires only leg and leveling feet assembly, providing you with a durable, unperturbed workspace.

One of the standout advantages of this table is its enhanced strength. The 3/16″ thickness can effortlessly handle more substantial materials and larger workpieces, making it the go-to choice for light industrial tasks. Additionally, the 5/8″ inch hole spacing remains versatile, allowing for secure positioning of various components, while the increased thickness adds stability and durability, ensuring your projects are executed with precision.

Incentives abound when opting for the 3/16″ thickness table over its 1/8″ counterpart. The increased thickness not only grants you the ability to tackle heavier materials but also provides a more stable foundation for intricate welding jobs. Furthermore, its robustness and rigidity make it an ideal choice for those looking to build custom jigs and fixtures for repetitive work, promoting efficiency and consistency in your projects. Whether you’re clamping, welding, or assembling, the Factory-Direct 3/16″ inch welding table sets the stage for a more versatile and capable welding workspace, perfect for light industrial endeavors.

CLICK HERE TO VIEW 3/16″ THICK FAB TABLES & OPTIONS

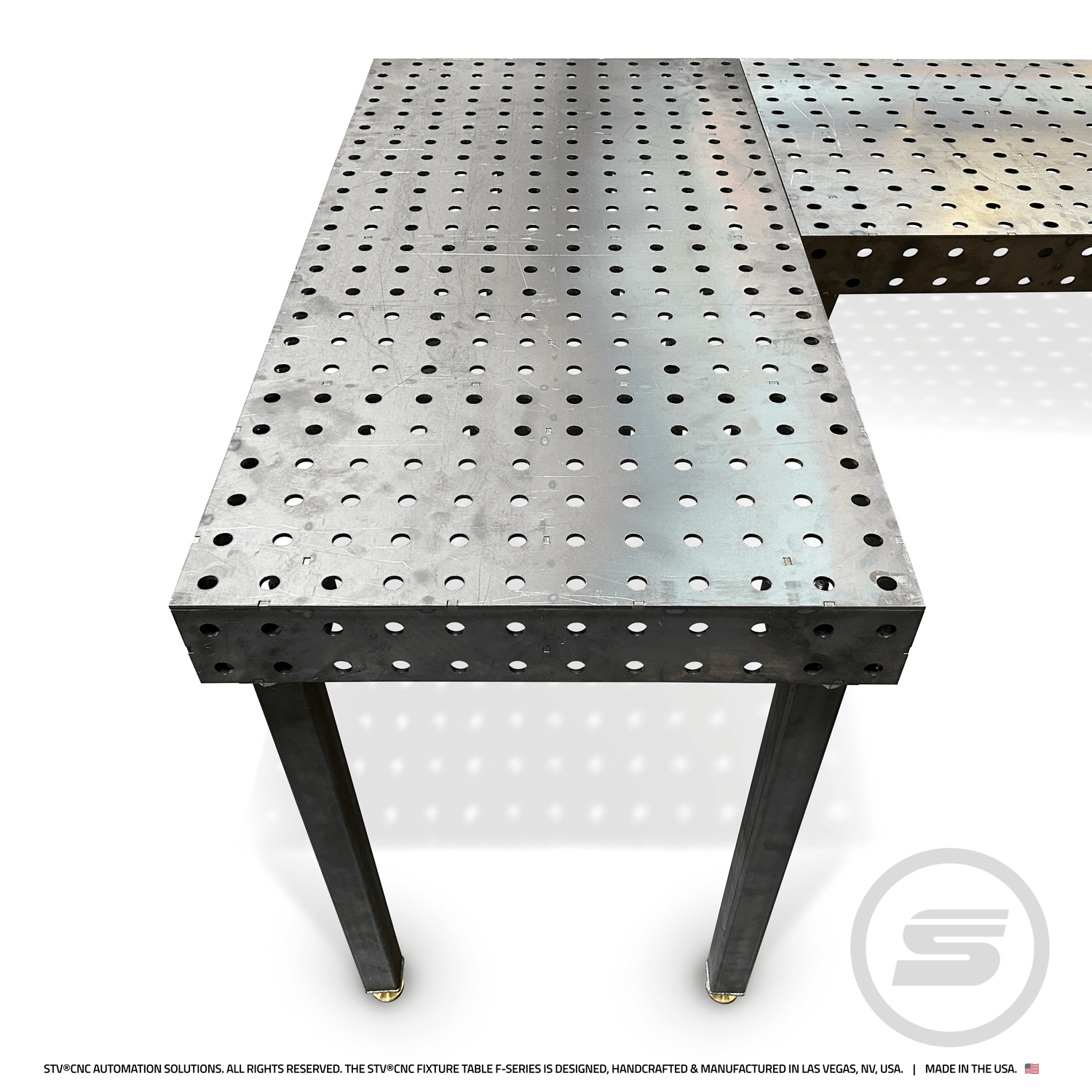

HEAVY-DUTY RATED – 1/4″ INCH THICK. The Factory-Direct 1/4″ inch thick welding table is a true powerhouse for heavy-duty fabrication projects. Not only does it offer uncompromising strength and stability, but it also introduces a modular concept that allows you to craft your own custom workspace. Picture this: a series of 2′ x 4′ tables, seamlessly interconnected to form the foundation of your manufacturing workspace. This innovation not only supports your fabrication needs but also embodies the spirit of American manufacturing resurgence.

HEAVY-DUTY RATED – 1/4″ INCH THICK. The Factory-Direct 1/4″ inch thick welding table is a true powerhouse for heavy-duty fabrication projects. Not only does it offer uncompromising strength and stability, but it also introduces a modular concept that allows you to craft your own custom workspace. Picture this: a series of 2′ x 4′ tables, seamlessly interconnected to form the foundation of your manufacturing workspace. This innovation not only supports your fabrication needs but also embodies the spirit of American manufacturing resurgence.

Compared to its thinner counterparts, the 1/4″ thickness of this welding table sets it leagues ahead. It’s purpose-built for tackling the toughest materials with ease, making it the preferred choice for demanding fabrication tasks. What truly sets it apart, though, is the ability to create a tailored workspace by connecting multiple tables. This modular raw fabricators table boasts a remarkable 432 smooth non-threaded bore holes, offering unparalleled tooling options and jig layout possibilities. This level of customization is a game-changer for any fabricator, allowing you to design your workspace for maximum efficiency and productivity.

Furthermore, investing in this beefier welding table not only empowers your fabrication projects but also aligns with the resurgence of American manufacturing. By choosing American-made products like this table, you’re contributing to the growth of domestic industries and supporting local american fabricator jobs. As you build your workspace, consider adding accessories like clamps, vices, and magnetic trays to enhance your fabrication capabilities further. The Factory-Direct 1/4″ inch welding table is not just a tool; it’s a symbol of craftsmanship, innovation, and the American spirit of making things happen.

Your STV®CNC Welded Fab Table is great for:

Want a Beefier STV®CNC Fixture Fab Table? You have options.

Hobby Table 1/8"

One workbench might be the ideal fit for you. We offer a single table setup at 1/8″ for hobbyists who have lightweight, quick projects or gigs that need to get done.

Light Industrial Table 3/16"

The 3/16″ inch thick fab table is highly recommended for an intermediate level, resistant to a wealth of projects. 1/4″ recommended for heavier projects.

Heavy-Duty Table 1/4"

Like it thicker? No problem. If you have a custom layout in mind & require a beefier layout of 2×4 tables, we can produce 1/4″ thick tables for heavy-duty production.

Upgrades: Customize your table with Add-ons.

TIG Handle Holder

Convenient and sturdy, the TIG Handle Holder is ergonomically designed to keep your TIG torch in place and in a safe position. One can position the bolted TIG Handle Holder in any direction and adjust the mounting hole locations as one sees fit to the convenience of your project tools’ resting area. (Includes 5/8″ hardware)

Magnetic Welding Gun Rest

Whether you require a side or table top rest, the Magnetic Welding Gun Rest is the efficient “Free Range Torch Mount” available for your fixture table. The Magnetic Mount can be used anywhere on your table or other ferromagnetic items like your welder unit itself and/or specific tool shelving. (Includes magnet & hardware)

Big Rack Tool Hanger

Every Fabricator loves a Big Rack. Running along the side of the fixture table, the Big Rack has 4 wide mounting notches for various tools or accessories you have to set & hang. The Big Rack is sent in Raw Material and easy to customize with your Company Logo. (Includes 5/8″ hardware)or

Short Stuff Bolted Shelf

Power Tools need a place to hang out. Go with the Bolted Short Stuff Power Tool Shelf to get all your necessary power tools all lined up and ready when you need them most. The Essential and Minimal Short Stuff Bolt-on Shelf is easy to love, hard to get rid of. (Includes 5/8″ hardware)

Helmet Hookers

During a project you tend to switch having to wear multiple hats at a time. Helmet Hookers makes it easy to swap out and hang up your Welder’s Helmet to then grab your Grinding Helmet Shield and switch up as you need. Helmet Hookers offer the quick reach versatility of hanging and not scratching your shields as you grind & weld away. ( Includes 5/8″ hardware; set of 2. )

Universal Torch Rest

Convenient and sturdy, the Universal Torch Rest is universally engineered to fit most torches and have it safely and secured to your table setup. One can position the bolted Universal Torch Rest in any direction & adjust the mounting hole locations as one sees fit to the convenience of your project tools’ resting area. (Includes 5/8″ hardware)

Round Handle Bar

The Pull Handle Towel Bar is easy to install and is perfect to hang your shop towels, clamps or other accessories as you see fit. The heavy duty, bolt-on 12″ inch solid round bar comes raw and ready to paint or customize. The Handle brackets are laser-cut and has an attached 3/4″ inch thick handle tube welded in-house. (Includes 5/8″ hardware)

Grinder Stand

Tired of changing out your grinder discs all the time? Select a Grinder Stand to have all your setup grinders lined up ready to unwind and grind! The Grinder Stand offers 6 location notches along the edge with power cord assistance and comes Raw and Ready to paint and customize as you please. (Includes 5/8″ hardware )

Grinder Wheel Disc Caddy

Keep it Together! Have all your grinding discs, sanding discs, wire wheels and abrasive accessories in one place with the Grinder Wheel Disc Organizer.

Welding Square

While working use the Welding Square as a helpful assistant to make sure all your checkpoints are square and at the exact plan specifications.

BOOK A TOUR OF STV®CNC

Las Vegas is home to our STV®CNC family of dedicated staff members. We would love to have you see our 50,000 sq. ft. Headquarter Operations. CLICK HERE TO BOOK A TOUR.

Financing: Assistance via First Citizens Bank or available lenders

Five Reasons to Finance your next purchase.

-

Get your equipment when you need it.

With financing, you can get the equipment you need now — and avoid making a hefty payment all at once.

-

Know what you’re paying each month.

You'll have a predictable monthly payment, which can help you plan for the future and budget for your other business needs.

-

Financing is simple — and quick.

With our simple online application that you can complete in minutes, you could get quick turnarounds on approvals.

-

Keep your cash reserves available.

Paying for your equipment over time means you can avoid tying up your cash all at once.

-

Reap potential tax benefits.

Financed equipment could be deducted as an operating expense in the period in which it’s paid and put into use — and that could reduce your overall cost. Payments are also treated as expenses on the income sheet, so there’s no need to worry about depreciation.

© 2023 First-Citizens Bank & Trust Company. All rights reserved. First Citizens Bank is a registered trademark of First Citizens BancShares, Inc. Not all applicants will qualify for financing. All finance programs and rates are subject to final approval by First-Citizens Bank & Trust Company, and are subject to change at any time without notice. Speed and performance are subject to applicant’s local connectivity and other factors outside First-Citizens Bank & Trust Company’s control. Supporting financial documentation may be required for any transaction with First-Citizens Bank & Trust Company. If a transaction is over $250k, then supporting financial documentation will be required. This is not intended to offer any tax advice or other advice. Applicants should consult with their tax advisors concerning their specific tax situations. Member FDIC. MM#12935

General Information about our In-house built tables.

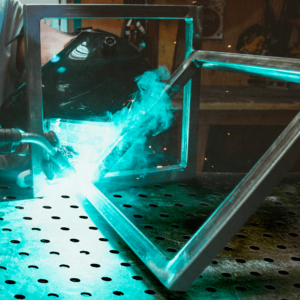

Welding fixture tables are indispensable tools for any industrialist, offering a myriad of advantages that bolster productivity, precision, and the overarching goal of bringing manufacturing back to the United States. These versatile fixtures provide a solid foundation for welding operations, and their benefits extend far beyond the workshop floor. Here are three key incentives for industrialists to take advantage with welding fixture tables:

Enhanced Precision and Efficiency:

• Welding fixture tables offer a flat and stable surface that ensures precise alignment of workpieces, reducing errors and rework.

• They enable consistent weld quality, leading to improved efficiency and faster, repetitive production cycles.

• By streamlining fabrication processes, they contribute to cost savings and a competitive edge in the market.

Versatility Across Industries:

• Welding tables find applications across a wide range of industries, from custom fab projects to automotive to construction and manufacturing.

• Whether in hobbyist (1/8″ inch), light industrial (3/16″ inch), or heavy-duty (1/4″ inch) environments, these tables adapt to diverse welding needs.

• Their adaptability makes them ideal for small workshops and mid-sized manufacturing sites alike.

Promoting American Manufacturing:

• Investing in welding fixture tables supports the growth of American fabrication jobs, fostering a thriving industry.

• These tables empower us to produce high-quality products domestically, reducing dependence on foreign markets.

• They embody the spirit of resilience, fighting to revive and sustain American manufacturing heritage.

Welding fixture tables are a cornerstone of modern industrial operations. Their precision, versatility, and contribution to American manufacturing growth make them an essential tool for industrialists aiming to excel in the competitive landscape. By incorporating these tables into their workflows, businesses can elevate their efficiency, quality, and commitment to revitalizing manufacturing in the States.

Our Fab Shop Tables are the unsung heroes of the metalworking industry, providing a sturdy foundation upon which precision fabrication projects are executed. These versatile workstations are designed with meticulous attention to detail, offering hobbyists & industrialists a stable and level platform to securely hold workpieces during the welding and grinding process. When considering welding fixture tables for your workshop, it’s essential to understand their significance in ensuring weld quality, efficiency, and safety.

One of the key advantages here of this raw fixture tables is its adaptability. These tables comes in one size but allows for an endless combination of modular configurations. Industrialists can select the amount of tables necessary to fit their specific project workspace. Whether you’re working on small-scale projects or mid-size industrial applications, this fabrication workbench table is just right for you. TIG vs MIG. Additionally, this basic, simple yet affordable fixture table is equipped with a grid of 432 precise Ø 5/8″ inch holes in a 2″ inch (center to center) grid pattern. These features enable welders to quickly position and secure workpieces using clamps, fixtures, or magnetic tools, streamlining the welding process and enhancing overall productivity.

Investing in a high-quality welding fixture table is a strategic move for any industrial operation. Not only do they provide a stable and secure work surface, but they also contribute to consistent weld quality, reduce rework, and promote a safer working environment. To maximize the benefits of welding fixture tables, welders should consider factors like table material, size, and additional features, ensuring that their choice aligns with the specific demands of their projects. Whether you’re a seasoned welder or just starting, a reliable welding fixture table is an indispensable tool for achieving precision and efficiency in your welding endeavors.

Customizing a welding table made of raw steel opens up a world of possibilities for tailoring your workspace to your specific needs. Raw steel provides an excellent foundation for customization due to its durability and weldability. To start, you can consider adding a specialized clamping system, such as vise grips or toggle clamps, to securely hold workpieces in place. Additionally, welding jigs and fixtures can be precision-fabricated and attached to the table’s surface, ensuring repeatable and accurate welds. The raw steel surface itself can be modified with slots or holes strategically placed to accommodate various tooling and accessories. Moreover, a durable powder coating or paint finish can be applied not only for aesthetics but also to protect the steel from corrosion. By customizing your raw steel welding table, you can create a versatile and efficient workspace that caters to your unique welding requirements, boosting productivity and weld quality.

Ideas on Customizing your Raw Steel Weld Tables :

- Lock into other tables in customizing your preferred Fab Shop Workspace

- Add a specialized clamping system (vise grips, toggle clamps).

- Propping up welded jigs & fixtures for precise welds.

- Custom Paint with durable powder coating or paint finish.

- Drill custom holes, supports and panels as needed.

- Fabricate and swap out for a preferred leg system.

- Adding integrated storage solutions (drawers, shelves).

- Swapping out for locking caster wheels for mobility.

- Inserting custom overhead lighting system for better visibility.

- Magnetic tool holders, accessory mounts, racks and trays for easy access.

- Fabricate support shelves for material, stock & completed pieces

- Install built-in power outlets for welding equipment.

- Fasten a cutting torch mount for added versatility.

- Attach adjustable workpiece support arms.

- Upgrade your table with an integrated cooling system for longer welding sessions.

- Customize a dedicated grinding station with a bench grinder.

- Setup Welding curtains or shield attachment for safety.

- Personalize an attached Weld Table Vise and Mount

- Bring in Tool carts or rolling cabinets to attached to the table

- Integrate built-in measuring scales for accurate placement.

These customizations can transform your raw steel welding table into a highly tailored and efficient workspace to meet your specific fab needs.

Damien –

➤ Click here to Read Reviews & Comments.