FEATURES

Your SparX 4800 Plasma Table base model comes with:

The SparX™ Plasma Table Series is the All-Modular Production Platform for Unified CNC Industrialists and is backed by our Golden Prestige™ Technical Support. Below are SparX™ Table features

TABLE & FRAME

-

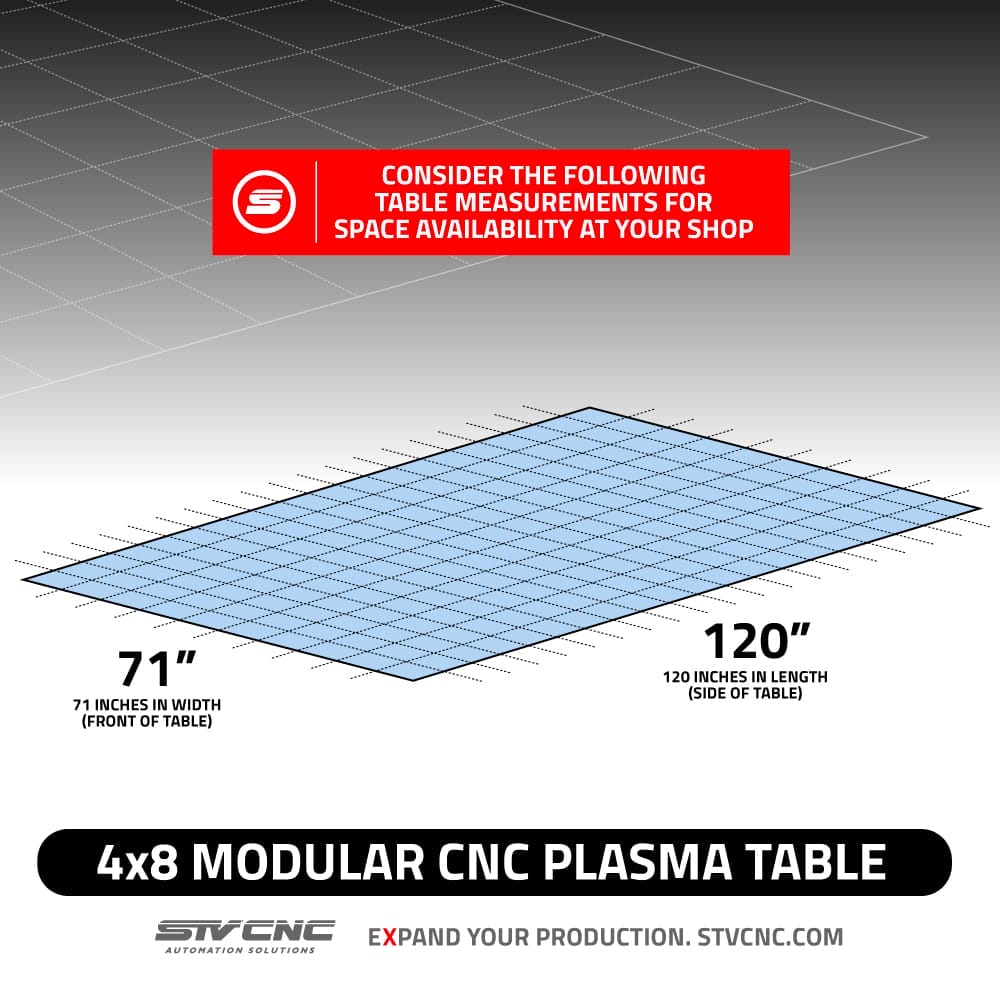

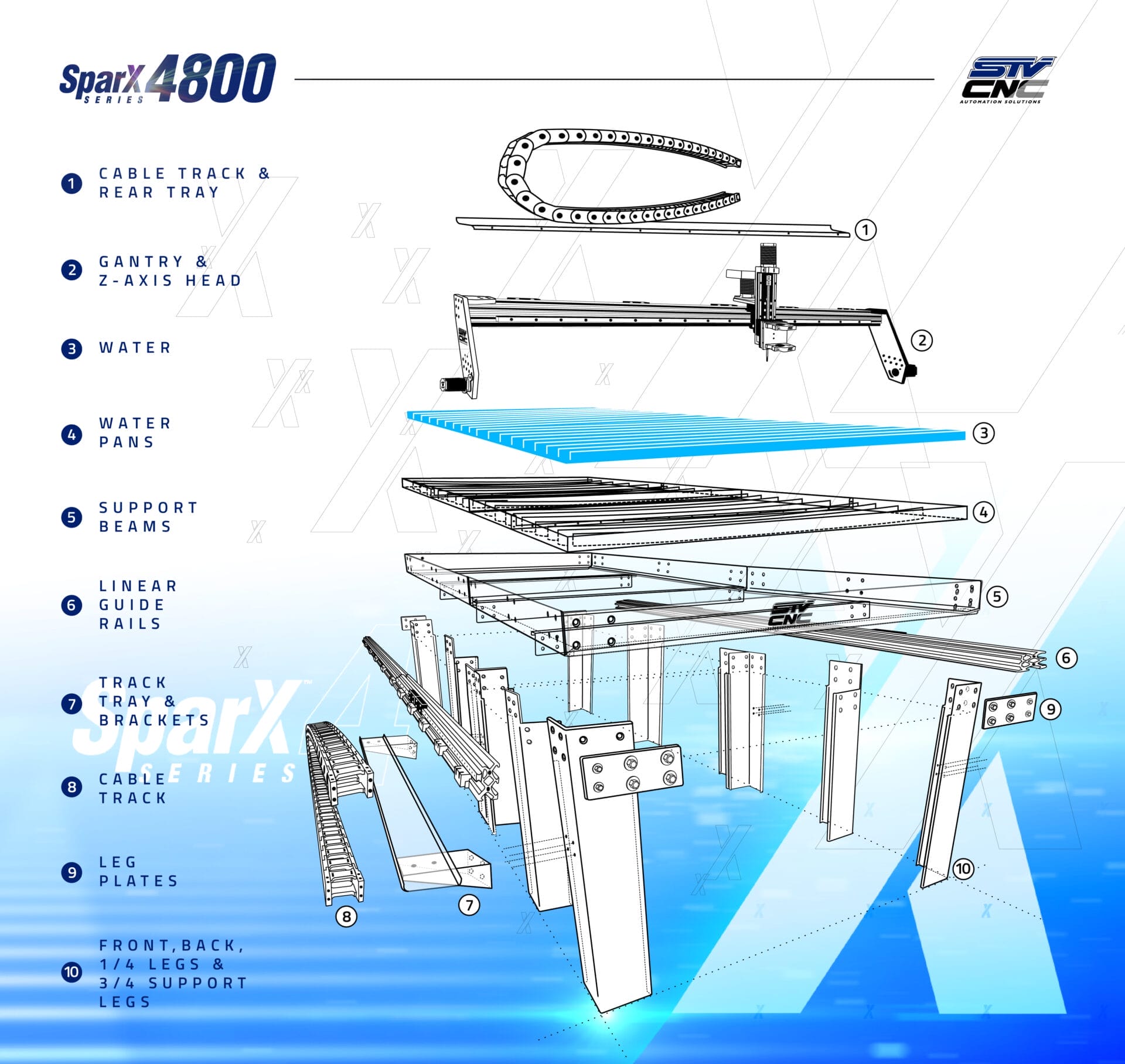

- SparX Plasma Table: This Wet/Dry Plasma Cutting Plasma Table has a Cutting Envelope of 8′ (L) x 4′ (W). This rapid & precise, SparX 4800 Modular Plasma Table is an open bolt-on modular frame (Assembly Required; Digital Assembly Manual included (Click here to view) that holds up to a 1.5″ inch steel plate and occupies a perimeter area of approximately 10′ (L) x 6′(W) x 5′(H). The 1200 lbs., 2-Crate Unit includes Four (4) Removable 3″ inch deep water pans and bolted leg brace supports for rigidity (Click here to view). (You will be required to provide 110 VAC for your table and 220-600VAC for your Plasma Cutter of your Choice.)

- E-Stop & USB Connectivity: Production platform has an detached Control box with an installed E-Stop button and USB Connectivity, avoiding the hassle of any unsupported or outdated hardware/cables. (6ft USB Connectivity Cable & Power cable included; Speak to your STV® Team Member if you require a sales quote for a longer cable.)

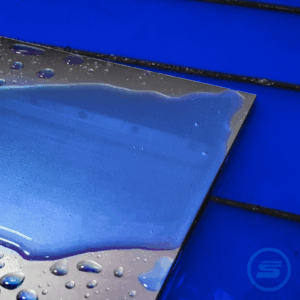

- Water Table: Includes a bolted 3-inch deep water pans (Click here to view) a set of Interchangeable 1.5″ flatbar Slats and welded slat holders (Click here to view). The Water pans hold about 87 Gallons in volume. We recommend filling your water pans with 4.3 Gallons of Plasma Guard STV®, Anti-Rust Solution (sold separately) and fill the rest of the water pans with Reverse Osmosis Water up to the top of the slats. Important to read action items on the Plasma Guard STV® Page to have it work as intended to, including maintaining your table and its pH Balance. (Click here to read more about Plasma Guard STV®)

UPGRADE ( Leveling Feet ): Upgrade your table with by adding Leveling Feet to your order (Click here to view). Includes Inner Support Brackets, Fasteners and Swivel Screw base. For any floor plan leveling issues, our skid-resistant leveling feet will come in handy on keeping a leveled table on your production grounds. Attaches to your STV®CNC Frame legs; raise or drop within a 2” inch range to your desired height.

THC, HEAD & SENSORS

-

- THC (Torch Height Control) is an included automatic feature that will assist with torch height by monitoring the plasma arc voltage. The voltage of the arc depends on a few variables, the variable that is most important for THC is the distance from the electrode to the work piece. As the torch moves further from the work-piece, the voltage of the arc increases. As the torch moves closer to the work-piece, the voltage decreases. This is where THC begins to work by monitoring this voltage and adjusting the Z-axis height to maintain an optimal cut height. (Click here to view)

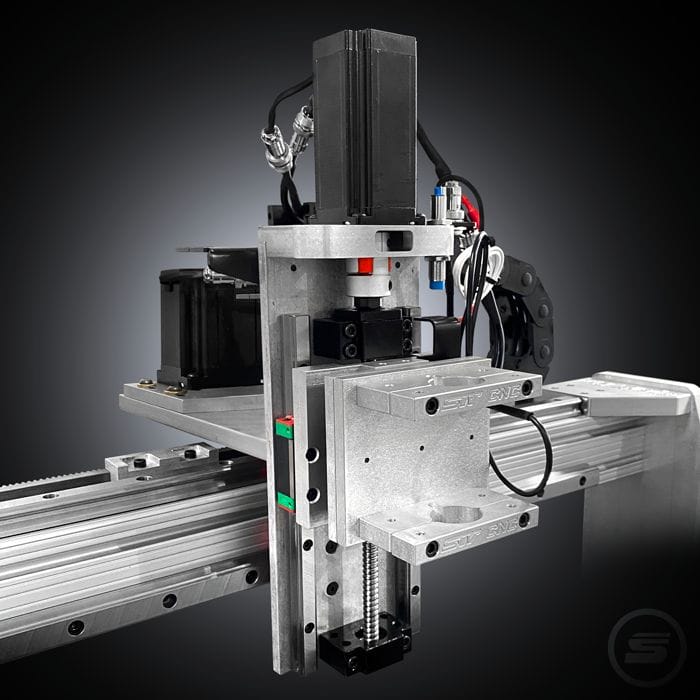

- Z-Axis Head: is an Open Front & Rear Head (with a Z-Axis Travel of 5.5″ inches; Click here to view), machined in-house and built on a precision ground billet ball lead screw with cuppler & Z-Axis Linear Stepper Motor Positioner. The Z-Axis Head also carries your X-Motor 1 of 3 of the 1:1 Ratio Direct-Drive Stepper Motor System. (Also See “Torch Setup” below for additional features of the Z-Axis Head.)

- Torch Setup: includes double bracket 4-bolt torch clamp, Magnetic Breakaway (for Torch Crash Prevention from tip-ups; Click here to view), Limit Switch (Floating Head Switch/Material Detection ensures material location and protects from misfires; Click here to view), Collision Switch (trips the collision sensor when it breaks off; Click here to view), Ohmic Sensitivity with White Ohmic Cable for Material Detection in Dry Cut Operations (Click here to view).

GANTRY ASSEMBLY & MOTORS

-

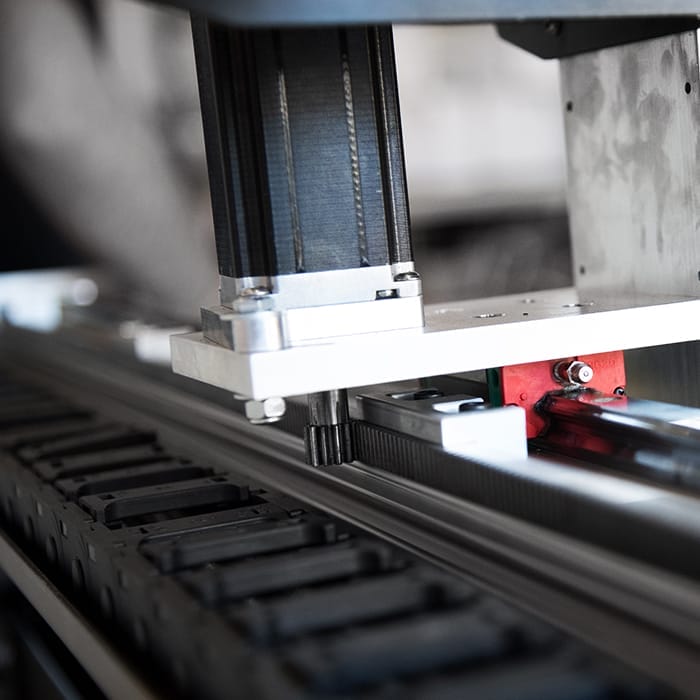

- Aluminum Gantry: is an assembled, extruded aluminum gantry with a 5.75″ inch Clearance and a Z-Axis vertical travel of 5.5″ inches (Click here to view). The Gantry & Table are equipped with a Standard Linear Guide Assembly and Standard Rack & Pinion for the Gantry (Click here to view) and Table (Click here to view). We recommend using WD-40, Scouring pads & Microfiber Towels to clean your table. Make sure to source Lithium Grease Blend (EP00 or EP000; Make sure the Lithium Grease Blend you select DOES NOT have MOLY or GRAPHITE in it.) (not included in purchase) & an Ares Grease Gun Kit (not included in purchase) to maintain your linear guides Carriage bearings.

- Stepper Motor System (1:1 Gear Ratio Direct Drive): Your Table includes four (4) Industry-standard Nema Stepper Motors. Your included Warranty protects your motors for One Year, but if you would like to extend the life of your motors further and increase the fluid motion of production cuts, one can look into upgrading to a 3:1 Ratio Gear Reduction System (Click here to view Standard Motors versus Gear Reduction System Comparison). The Motors are backed by Durable Automation Wiring, Handcrafted & Labeled in-house at STV®CNC (Click here to view). The STVCNC Gear Reduction Motor System is also backed by our Advanced Cable Management (Click here to view) that carries the Automation Wiring & Power Cabling out to the Control Box on the left side of the plasma table (Click here to view).

SOFTWARE

-

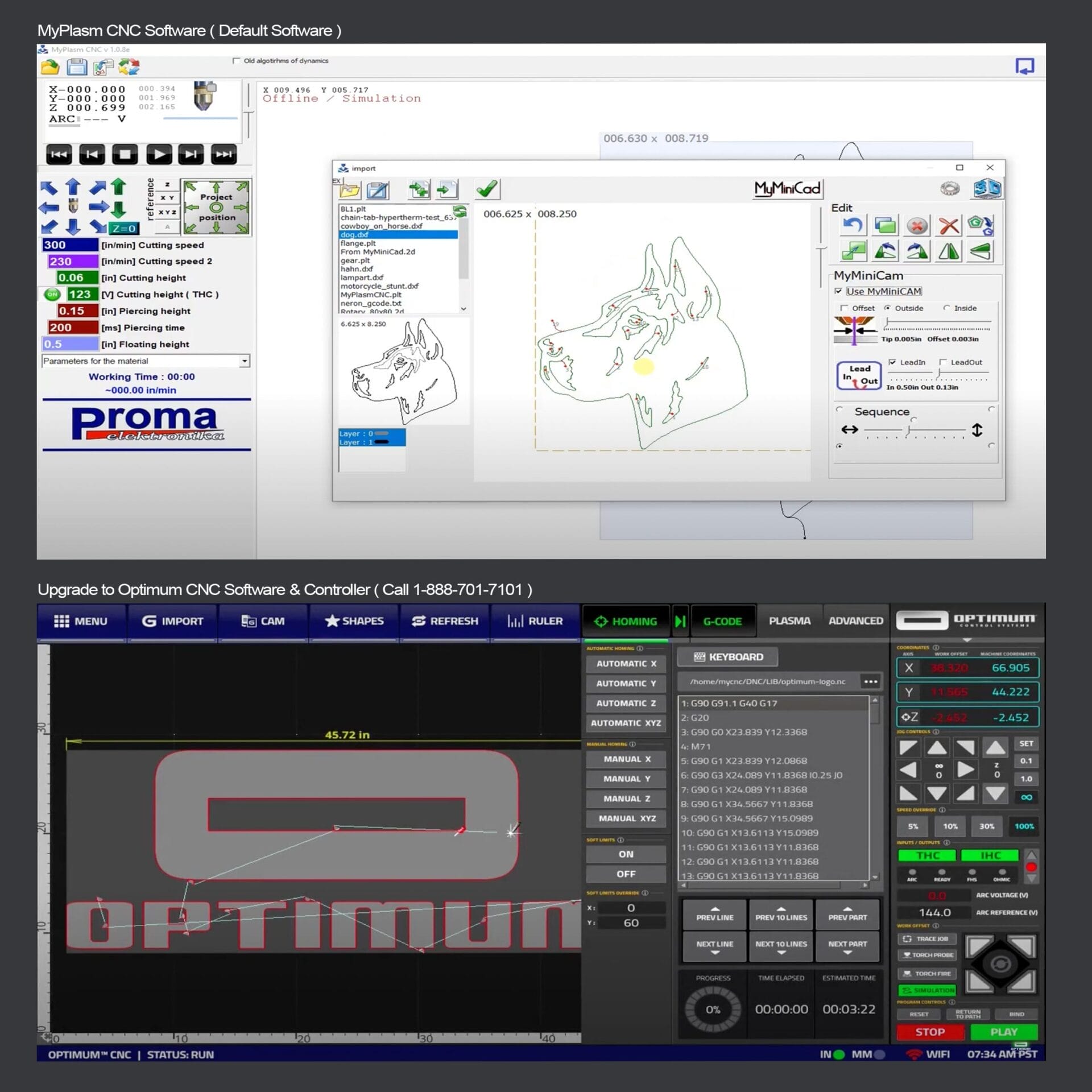

- Downloadable MyPlasmCNC & Controller: The Standard Control System, MyPlasmCNC, is the basic CNC Control System for Beginners in Fabrication or industrialists who desire to learn a less complex CNC cutting program. The MyPlasm Software & Controller has its essential functions and its limitations, but is backed by the STV® Team for Troubleshooting as we offer Step-by-Step Tutorials that guide you through basic software & table operation as well as a Private Community of 2300+ Table Owners for networking and additional knowledge base. You will also have pertinent Manuals & Documentation that will assist you within your Owners Document Access Link. (MyPlasmCNC works with File Types: .dxf, .plt, .tap, .2d, .hpgl files. It also includes MyMiniCAD to draw out parts for production. We recommend using Inkscape and/or QCAD to facilitate design & cut file creation.)

- 1000+ DXF Cut files: Included in your purchase will be your “Table Owners Access Link” which contains all manuals, documents, tutorials, video art sessions and a library of 1000+ DXF cut files to start with.

- STV®CNC Manufacturer’s One Year Warranty. In Fabrication, issues happen & we’re here for you. Within your warranty, we can quickly ship out replacement parts that are damaged or defective. Ground shipping for replacement parts is covered in your warranty, any additional faster expedited services will be covered by the table owner. Moreover, our table components are always in-stock and affordable even after your warranty has expired.

TECH SUPPORT

VIP ACCESS

- With your purchase you’ll gain Access to the STVCNC Private Plasma Table Owner’s Facebook Community, where we share files, skills and settings amongst the 2300+ Members of our Worldwide Fabrication Network. With STV®CNC you’ll gain access to purchasing Hypertherm® Consumables/Cartridges and Plasma Guard STV® and obtain in-house STV®CNC dedicated tech support for software, product & table operation.

➤ OPTION 1: PICKUP. You have the free option of picking up your palletized item, available at our facility.

6160 N. Hollywood Blvd. #110, Las Vegas, Nevada, USA 89115 MAP ▶

➤ OPTION 2: SHIP. $1200 for Continental U.S. Shipping. Weight: 1200 lbs. (2 Crates). Delivery zone selection may change ship cost. Excludes Hawaii, Alaska & Puerto Rico (see “Sea Freight” below).

SHIPPING QUESTIONS

➤ Are there any ADDITIONAL SHIPPING COSTS?

Any of the next 5 scenarios may apply in the shipping of your item.

01. COMMERCIAL DELIVERY – No additional charges, unless it has limited access. (See Limited Access.)

02. LIMITED ACCESS: Add +$200

If the delivery address is a Farm, State municipality, Prisons, Schools or a location with a gated entrance.

03. RESIDENTIAL DELIVERY: Add +$150

If you are having the crates be delivered to your home OR if you have a Shop and a Home on the same property, a Residential charge will be required.

04. LIFTGATE: Add +$150

If you do not have a forklift onsite to unload the crates from the truck, a Lift Gate charge will be required.

05. SEA FREIGHT – For International orders, you will need to cover U.S. Ground Shipping from Las Vegas to the Port of your choice. After that, you will need to organize your choice of Sea Freight to pick up at that port and have it shipped to your location. If you have a moment, search for Sea Freights to your location and inform us with the Port location we will be shipping to within the U.S. and we can go from there.

➤ What if I don’t want to ASSEMBLE the table?

Our Plasma Tables come with a user-friendly instruction manual that will guide you through bolting together the Legs, Support Beams, cable trays, brackets and Water pans. We also sell fully built PRO Plasma Tables with Welded Frames that ship flatbed directly from our Factory to your front door. Please check with your STV®CNC Sales Agent for more details on the Freight Distance Cost. Pickup is also an available option for this product line.

➤ What happens at DROP OFF?

Our Freight Carrier will deliver your crates to the location provided. Please advise your STV®CNC Sales Representative with any delays, gate codes, special entry requirements or deadlines that might hinder or prevent delivery attempts. Please check the crates before Delivery is completed to ensure no damages were incurred during transportation. At the time of ordering we will require you to confirm if your location is residential or commercial and if you will require a lift gate upon delivery. If you do not have a forklift, a “lift gate” is an additional service cost in unloading your crate from the delivery truck.

➤ How do you SHIP your plasma tables?

We have a couple different ground freight carriers. The shipped plasma table consists of one main crate for the table and an elongated crate for the linear guide rails. Smaller tables like the 2×4, 4×4 and 5×5 arrive in one single crate. Pickup at our Facility is also an available option provided on a shrink-wrapped palette.

➤ Do you ship to Canada, Dubai, Hawaii, Mexico or International?

Yes, For International orders or locations out of the Continental United States, you will need to cover U.S. Ground Shipping from Las Vegas to the Port or Terminal of your choice. After that, you will need to organize your choice of Ground or Sea Freight to pick up at that port and have it shipped to your location. If you have a moment, search for freight carriers to your location and inform us with the Port location we will be shipping to within the U.S. and we can go from there. You will be required to delegate the international brokerage and fees.

➤ Can I pick up my crates at the Terminal?

Potentially, depending on your location and whether or not you have a truck or trailer able to pull 600 to 1500 lbs. of weight (depending on the table size you purchased.) Check with your sales agent for trailer fitting.

PAYMENT

➤ TAXES: If you reside in the State of Nevada, you will be charged Nevada Sales Tax. Sales tax will not be added to orders if the purchaser resides outside of the State of Nevada.

➤ PAY BY PHONE: We can take a payment via phone. We’ll follow thru to provide you with a “paid in full receipt” and confirm the shipping address before sending the purchase order into production.

➤ PAY BY INVOICE: We can send you an interactive invoice of the items requested where you can tap on the “Pay Now” Tab to proceed with a Credit card, Venmo, Amazon Pay, PayPal or Wire transfer.

➤ REQUEST AN ESTIMATE: We can send you an estimate price quote prepared of the items requested.

➤ PAY ONLINE: There are products on our website that require lead time check and/or calculation of flatbed hotshot trucking distance to your location. A full online experience will not be possible, one will have to call 1-888-701-7101 to verify your order’s details.

➤ PAY VIA SCHOOL/GOVT/UTILITY: For Public Universities, Schools, Government agencies & Utilities, please provide your Purchase Order with Net30 Terms along with your vendor package.

➤ PAY VIA FINANCING: We also via third-party offer financing for your purchase. One can quickly apply for financing and be approved in as little as 3 minutes. Read more

We recommend the following aside from your table purchase. Questions? Speak with our support staff at 1-888-701-7101

Equipment & Material Recommendations:

- Plasma Guard STV®: Anti-rust solution for your table that protects your water pans, slats and cutting pieces from rust. Read more

- Hypertherm® Consumables: These Consumables are for your Mechanized Torch in the cutting process VIEW.

- Plasma Cutter Power Setup: VOLTS: 200-600VAC, AMPS: 50 (Contact Plasma Manufacturer for Electrical Setup.)

- Computer/Control Box Power Setup: VOLTS: 110, AMPS: 20 (Contact a Professional & Certified Electrician for Electrical Setup.)

- Plasma Cutting System & Torch: Hypertherm® Powermax45®XP or a Hypertherm® Powermax45 SYNC® Plasma Cutting Unit with a Mechanized Torch.

- Air Compressor: Plasma Cutting Units require an air compressor to provide quality cuts with minimal dross. Source an Air Compressor with a Minimum of: Capable of 6 SCFM at 90 PSI. You are more than welcome to check with other owners in the Private Community to help your choice.

- Air Dryer: Plasma Cutting Units require dry air to provide cleaner cuts with minimal dross. Source a Refrigerated Air Dryer or dessicant filter system that will match your compressor specs. You are more than welcome to check with other owners in the Private Community to help your choice.

- Computer: If you plan on designing your own cut files, you may want to source a design computer or laptop with higher processing power for File Designing & File Storage. Minimum of 3 GHz Desktop Computer or Laptop, WindowsXP or newer with 16 GB RAM, 250 MB storage, 2 USB ports.

- Metal Supply: Source your nearest Metal Sheet Supplier in your area.

- Water Agitation: We recommend if one cuts a wide variety of materials on their plasma table, to install a water filtration system that agitates the water. Install an Aerator, Bubble Muffler or Water Filtration System for Surface Agitation, Oxygenation & Water bed Gas Dissipation. Clean any submerged, cumulative surface areas or Hydrogen gas trapped pockets of Aluminum particles in your water bed. (Especially prevention against the mixing of aluminum particles with mild steel particles in your water bed.)

- Safety & Prevention: Dust Removal system, PPE: Eye & Ear Protection, PPE: Respirator, On-site Ventilation

Tools for Table & Assembly Recommendations:

- Sealant: For Modular Tables Water pan Assembly, we recommend you sourcing 100% WATERPROOF SILICONE of your choice to seal the gap between each water pan. Other sealing options are welding your water pans or installing gaskets. Many customers have custom cut their water pans to install a water agitation/filtering system, additional advice on this is available in the private Facebook community.

- Caulking Gun: Assists in sealing the water pans with the application of waterproof silicone.

- Exposure: This is an INDOOR Plasma Table. Not recommended for outdoors or exposure to an outdoor environment. Maintain table & wipe linear guides down with WD-40 and scouring pads regularly.

- Interference: The crossing of cables may cause interference. Make sure that your TORCH CABLE does not touch the Z-Motor at the top of your Z-Axis Head.

- Grounding Rod: Install an 8′ foot Earth Grounding Rod to prevent interference. We recommend installing the earth grounding rod to avoid material waste & any possible mechanical ghost movements that interference may cause.

- .Hypertherm® Grounding Recommendations: To make sure of personal safety and correct operation, and to decrease electromagnetic interference (EMI), the plasma power supply must be correctly grounded. Refer to the Safety and Compliance Manual (80669C) for more information on grounding. For mechanized cutting systems, refer to EMI grounding and shielding best practices in the Powermax45/65/85/105 SYNC Mechanized Cutting Guide (810480).

The plasma power supply must be grounded through the power cord according to national and local electrical codes.

1-phase service must be of the 3-wire type with a green or green/yellow wire for the protective earth ground. 1-phase service must comply with national and local requirements. Do not use a 2-wire service.

3-phase service must be of the 4-wire type with a green or green/yellow wire for protective earth ground. 3-phase service must comply with national and local requirements

- Digital Caliper: Helps measure cut outs & metal sheets.

- Magnet Stick: Helps remove cut pieces/debris/tip-ups off of the table and/or water pans.

- PPE Gloves/Eye Protection: Work Gloves to help handle any cut parts that may still be hot and transfer of metal sheets in production. Consider Eye protection from any debris or Plasma Cutting glare or sparks. Follow Safety Precautions in your Hypertherm® Safety Guide.

- Zip ties: help keep cables organized & prevent interference as you strap cables & torch to your Cable Swing arm. Important: Make sure you UNCOIL your cables. This includes the excess of your Torch cable, the PC cable and Grounding Work Lead Clamp.

- Other tools for Assembly: Standard & Millimeter Allen hex key and wrench set, Hex Socket/Wrench Set, Hex Socket Drill, Level, Large Pliers, Rubber Mallet for slat installation, Tape Measure, Utility Safety Gloves/Latex Gloves and Two short wooden blocks of the same length to assist in gantry alignment.

Clean Time / Maintenance Recommendations:

Cleaning time is usually between 30 minutes to 3 hours, depending on what water pan coating you have chosen to apply. It may take longer if water pans are raw steel.

- How do Table Owners prep their water pans for easy cleaning? Many of our Table Owners have chosen to coat their water pans in different ways with: POR 15, & high temp (high aluminum) silver paint, Marine Grade Epoxy, Duralux Marine Primer & Paint, Powder Coating, Powder Coating with Anode rods, Ospho & copper-infused boat bottom paint, Water District 3M Powder Coat product, 1/8″ thick layer of Flex Seal.

- WD-40 & Scouring pads & Microfiber Towels: Assists in table maintenance and cleaning.

- Lithium Grease Blend (EP00 or EP000) & an Ares Grease Gun Kit: Assists in table maintenance for Carriage bearings.

- Water Pump: Assists in table maintenance and water removal.

- Green Light Checklist: We have prepared 8 key points to check at your site of production to ensure a successful cut. Visit the Green Light Checklist at www.stvcnc.com/greenlightchecklist

- Other tools for Cleaning: Tools many Table Owners have used: Needle Scaler, Scraper, Wire Wheel, Weed burner, Wet Sand Blasting, Shop Vacuum, evaporative cooler pump, Red Tip Pressure Washer.

➤ We also recommend one get the approval of their spouse. Sorry we don’t make the rules, they do.

➤ FACTORY-DIRECT. This item is IN-STOCK and ready to ship from our Factory to your shop or location. We pride ourselves in managing and organizing our manufacturing output of CNC Tables as they roll off our Factory Production Line. Get your order in to be queued up for Production and Delivery today. Up to date lead times are available by calling your STV® Sales Agent at 1-888-701-7101.

➤ For International Orders or locations out of the Continental United States, you will need to cover U.S. Ground Shipping from Las Vegas to the Port or Terminal of your choice. After that, you will need to organize your choice of Ground, Shipping Carrier or Sea Freight to pick up at that port and have it shipped to your location. If you have a moment, search for freight carriers to your location and inform us with the Port location we will be shipping to within the U.S. and we can go from there. You will be required to delegate the international brokerage and fees. Call 1-888-701-7101 for more info.

SUPPORT

The SparX Modular Platform is backed by our Golden Prestige℠ Technical Support that offers solutions across a wide range of customer support methods like Table Troubleshooting, Live Support via remote assistance, as well as Hypertherm® Unit Troubleshooting well before any escalation occurs and enjoying the ease of having us delegate any replacement parts to prevent any extended amounts of down-time.

Table & Software Dedicated Live Support

Our STV® Team Members are knowledgeable in troubleshooting topics on Table Operation, maintenance & software during business hours. We love to dedicate our full attention to troubleshooting. You can fill out the Support Ticket at www.stvcnc.com/support and we’ll contact you directly with the solutions to meet your needs. We’re available via phone with Tech Agents on queue, feel free to call 1-855-974-4413. Time is essential in getting you up and running on the basics for table operation, software and daily tasks. After watching our tutorial videos, we are here for any one-on-one phone calls or remote assistance where all support ends with solutions. You also will have additional support via our Private Nationwide Facebook Community.

After Hours Active Community

We currently have over 2,300+ savy and successful Plasma Table Owners who spread across various industries. The Facebook Private Community is healthy, positive and always forward moving for improvement & growth. https://www.facebook.com/groups/470011710395310/

Connect with a Neighboring STV®CNC Table Owner

We have thousands of STV®CNC Plasma Table Owners spread out across the nation. Reach out to us 1-855-974-4413 on having you connect with others near your location. Click here to find a SparX Table Owner near you.

Step-by-step Instructional Videos

We want to make sure we speed up you and your team’s learning curve. We’ve made sure to produce helpful step-by-step tutorial video sessions to make that happen. Time is essential in getting you up and running on the basics for table operation, software and daily tasks. After watching our tutorial videos, we are here for any one-on-one phone calls or remote assistance where all support ends with solutions.

Replacement Parts & Product Support

STV®CNC is a proud OEM Distributor for all Hypertherm® products, including Plasma Cutting Units, consumables, cartridges & accessories. Issues happen & we’re here for you. Within your warranty, we can quickly ship out components that may have failed over extensive wear & tear. Our table components are always in-stock and affordable even after your warranty has expired. We also provide tech support for Hypertherm® products before escalation.

Troubleshooting Topic? Please contact Tech Support at www.stvcnc.com/support

ADD-ONS

These STV®CNC add-ons are additional accessories that one can customize and upgrade their table. Feel free to tap on Product details to read more on each Add-on and its benefits.

Plasma Guard STV®

Anti-Rust Solution: Decrease production dust/debris, preserve your water pans & avoid any oxidation. The Blue Anti-Rust Solution by PICO Chemical arrives in a 5 Gallon Bucket. Tap on the button for Dilution Rates for your Table Size. Call 1-888-701-7101 if you need a 55Gal / 330Gal size.

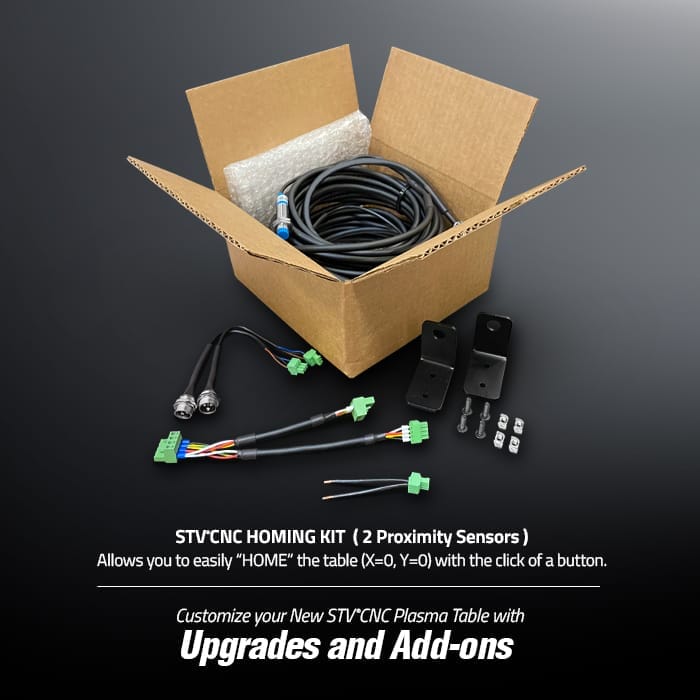

Automatic Homing Kit

On a Daily use, Proximity Sensors make “Homing the Table” fast, easy and worry-free. To increase time efficiency we’ve produced an in-house STV®CNC Automatic Homing Kit. Two Proximity Sensors Included with Cabling, brackets, fasteners, control box connectors and a manual to automatically set your table to X=0, Y=0.

Windows Laptop

Windows Laptop with MyPlasmCNC Controller is dedicated solely for “Table Operation” with USB Connectivity. We recommend sourcing a secondary laptop with enough processing power for file storage & heavy Design/CAD programs using a USB to transfer files to this laptop when needing to cut. Laptop Make and Model may differ upon availability. (This Windows Laptop PC is “NOT” to be confused with the Linux MiniPC offered with the Optimum CNC Controller.) The MyPlasmCNC Controller Software is downloadable to install as desired, if this add-on is not selected. CALL 1-888-701-7101 TO UPGRADE YOUR CNC CONTROLLER & SOFTWARE TO OPTIMUM CNC.

Leveling Feet (Skid-Resistant)

Includes Inner Support Brackets, Fasteners and Swivel Screw base. For any Floor plan leveling issues, our skid-resistant leveling feet will come in handy on keeping a leveled table on your production grounds. Attaches to your STV®CNC Frame legs; raise or drop within a 2” inch range to your desired height.

3:1 Ratio Gear Reduction System

The STV®CNC Gear Reduction System are 3 (X, Y & Z) separate mounted stepper motors with belt-driven gears to increase precision & gliding fluidity. Handcrafted Cable Wiring fastens into your Plasma Table. The Kit is designed, manufactured, assembled & tested in-house.

Powerstation Cart

42″ inch Mobile Workstation Cart. Maximize your workspace with this Double Shelf PC standing desk. Includes Adjustable height, 15′ ft. Triple Outlet Power Strip, Cabinet w/ Lock, Gliding Tray & Locking Caster Wheels.

Hypertherm® Cartridges

STV®CNC is a Proud, Leading Hypertherm® OEM Distributor offering the best pricing in Hypertherm® Plasma Cutting Units, Consumables/ Cartridges, Replacement parts & Accessories. Tap the button to see the Cartridge Ordering Hub we’ve built.

FACTORY TOUR

BOOK A TOUR OF STV®CNC

Las Vegas is home to our STV®CNC family of dedicated staff members. We would love to have you see our 50,000 sq. ft. Headquarter Operations. CLICK HERE TO BOOK A TOUR.

HYPERTHERM®

IMPORTANT: Depending on the model you select, Plasma Cutting System lead times fall into a queue list for each model series as we receive them from Hypertherm® and out to you. In 100% transparency, we strive to deliver a well-rounded experience. Feel free to call us to chat about lead times. 1-888-701-7101.

Hypertherm® Powermax45 SYNC® $3300

1/2″ INCH PIERCE VIEW PDF

Includes Cutting System, 25ft SmartSYNC® Mechanized Torch, Work Lead, Set of SYNC® Cartridges, Ohmic Rings, Cut Charts & Manual, USB Instructional.

6 Year Warranty for Unit & 1 Year for Torch.

INCLUDES FREE 8FT OPTIMUM CPC INTERFACE CABLE ($200 VALUE)

Hypertherm® Powermax65 SYNC® $4450

5/8″ INCH PIERCE

Includes Cutting System, 25ft SmartSYNC® Mechanized Torch, Work Lead, Set of SYNC® Cartridges, Ohmic Rings, Cut Charts & Manual, USB Instructional.

6 Year Warranty for Unit & 1 Year for Torch.

INCLUDES FREE 8FT OPTIMUM CPC INTERFACE CABLE ($200 VALUE)

Hypertherm® Powermax85 SYNC® $5750

3/4″ INCH PIERCE

Includes Cutting System, 25ft SmartSYNC® Mechanized Torch, Work Lead, Set of SYNC® Cartridges, Ohmic Rings, Cut Charts & Manual, USB Instructional.

6 Year Warranty for Unit & 1 Year for Torch.

INCLUDES FREE 8FT OPTIMUM CPC INTERFACE CABLE ($200 VALUE)

Hypertherm® Powermax105 SYNC® $7450

7/8″ INCH PIERCE

Includes Cutting System, 25ft SmartSYNC® Mechanized Torch, Work Lead, Set of SYNC® Cartridges, Ohmic Rings, Cut Charts & Manual, USB Instructional.

6 Year Warranty for Unit & 1 Year for Torch.

INCLUDES FREE 8FT OPTIMUM CPC INTERFACE CABLE ($200 VALUE)

Hypertherm® Powermax125® $10100

1″ INCH PIERCE VIEW PDF

Includes Cutting System, 25ft Duramax® Hyamp™ Mechanized Torch, Work Lead, Standard Consumables, Cut Charts & Manual.

6 Year Warranty for Unit & 1 Year for Torch.

INCLUDES FREE 8FT OPTIMUM CPC INTERFACE CABLE ($200 VALUE)

ADAPTERS

Adapters are a list of Cables, Hand Torches or Mechanized Torches if you already own a Hypertherm® Plasma Cutting System or if you require an “additional” Hypertherm® Accessory for the purchase of a new plasma system. If you are purchasing a New Plasma System, it already includes the necessary Mechanized Torch & STV®CNC CPC Cable that applies along with the unit.

STV®CNC CPC Interface Cable

Add this item to your cart “ONLY” if you are an existing Hypertherm® Plasma System Owner & require a CPC interface cable. If you purchase a Plasma Table with us & decide to use your personal plasma system or decide to purchase one elsewhere, you will need to purchase this item to connect the plasma cutting system to our Control Box.

Hypertherm® Hand Torch (25ft.)

Select “ONLY” if you are an existing Hypertherm® Plasma System Owner & require a separate Hand Torch. The 25 foot Duramax® 75° hand torch is well suited for a variety of applications such as gouging, fine feature cutting, extended reach cutting, and flush cutting. The ergonomic design of the 75° torch is perfect for normal cutting.

FINANCING

Financial Assistance for your STV®CNC Order is available through First Citizens Bank or through an assorted list of top financing lenders. Quicken Equipment Ownership with flexible terms that work best for your operation.

STV®CNC offers financial assisting options through First Citizens Bank or through an assorted list of available top lenders who offer different tiers of financing. Finance essential CNC equipment, Plasma Tables or Router Tables for your business. Expand your financing options. Get the resources you need to make your business flourish with an exceptional financial backing with options that work best for you. With experience working with small businesses we know what it takes to start, expand and have the correct measures that will support your daily operations along with any flexible small business loans and financing solutions to meet your needs.

General Information about our In-house built CNC Plasma tables.

The toughest plasma tables on the market.

- Plasma tables with high-end machine features in a small frame.

- Automated plasma cutters that can handle metals of various widths.

- CNC plasma table that’s perfect for businesses of all sizes.

When you need the best plasma cutting table for your company, then look no further than the STV®CNC SparX™ 4800 Plasma Table. This automated plasma table can handle all sizes of metal, from a half-inch thick and beyond. All of our CNC plasma tables feature high-end machinery that helps reduce the time spent creating while increasing consistency. This industrial level plasma cutter is perfect for companies both big and small, especially those looking for their first plasma table. If you need a rugged and reliable automated plasma cutter, then the STV CNC SparX™ 4800 Plasma Table is perfect for you. Get your CNC plasma table online today.

- Uses Windows OS interface

- Several advanced attachments included

- Dry or water pan options available

- Selectable input power

We have applied the technologies of high end, industrial level CNC plasma tables to the entry level market. The STV®CNC SparX™ Plasma Table Series incorporates high end machine features and capabilities, in a smaller package. Using our high accuracy stepper motors for speed, control and smooth operation and combining it with ground linear bearings and guide rails results in consistency and speed that is unrivaled in the industry. Additionally, our tables are built tough and designed to easily handle half-inch steel plates (but they can handle more). Made in the USA.

Reviews

There are no reviews yet.