FEATURES

Your SparX™ PRO4 Plasma Table base model comes with:

The SparX™ PRO Plasma Table Series is the Welded Tube Frame Production Platform for Unified CNC Industrialists and is backed by our Golden Prestige™ Technical Support. Below are SparX™ PRO Table features

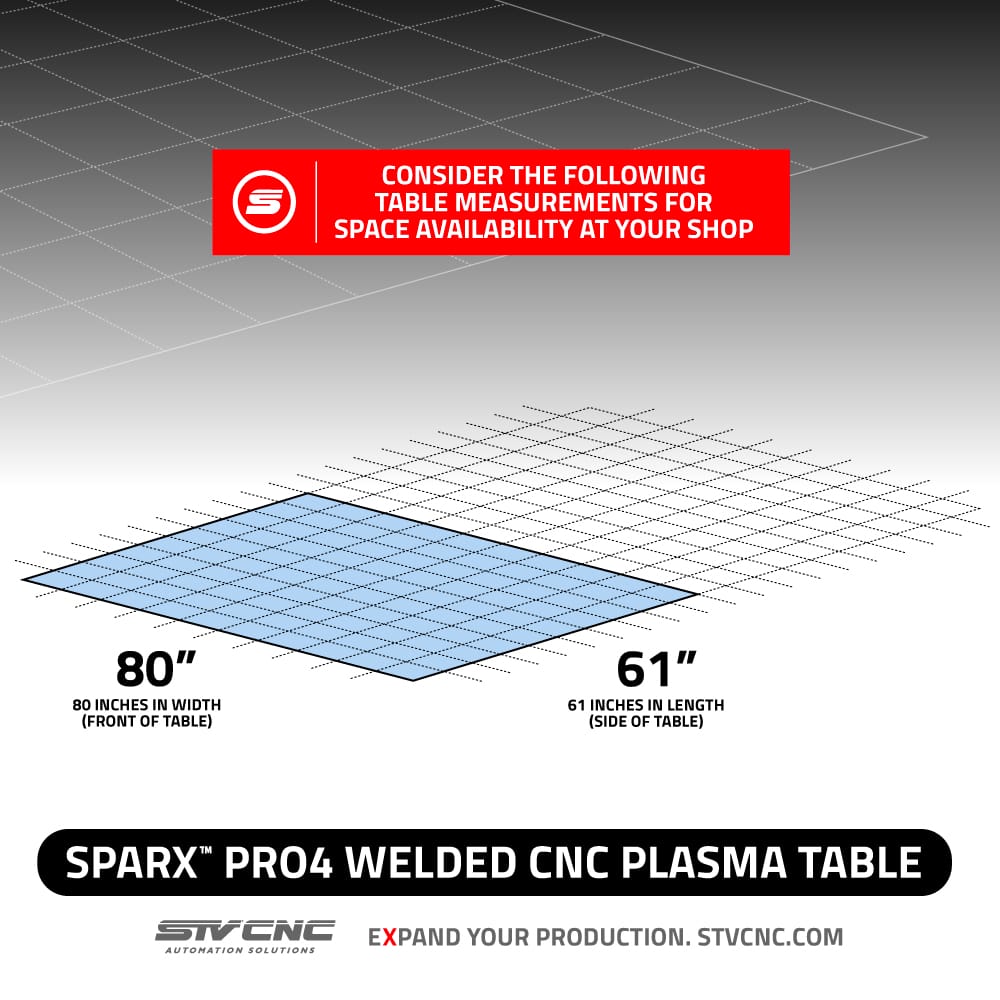

➤ Cutting Envelope: 4′ (L) x 4′ (W)

➤ Table Footprint: 84″ (L) x 72″ (W)

➤ Table Area: 42 ft²

➤ Water Table; Wet Plasma Cutting Operation VIEW. (Plasma Guard STV® Anti-Rust Solution sold separately, See “Add-ons”.)

➤ Dry Table; Dry Plasma Cutting Operation VIEW (Ideal for Ohmic Sensing)

➤ 110VAC for the plasma table and you’ll need 220-600VAC for your choice of a plasma cutting system (sold separately).

OPEN WELDED 3″ TUBE FRAME ( No Assembly Required )

➤ Frame holds up to 2″ inch steel plate.

➤ Welded Lower Leg Brace Supports for rigidity VIEW

➤ Long, Welded Uni-Pan™ (Single Welded Water Pan) VIEW

➤ Uni-Pan™ Leak-Checked (Single Welded Water Pan) VIEW

Z-AXIS MACHINED HEAD

➤ Double Bracket 4-BOLT System VIEW

➤ Billet Precision Ball Lead Screw VIEW

➤ Z-Axis Travel: 5.5″ inches

➤ Collision Switch (Sensor) VIEW

➤ Limit Switch (Material Detection) VIEW

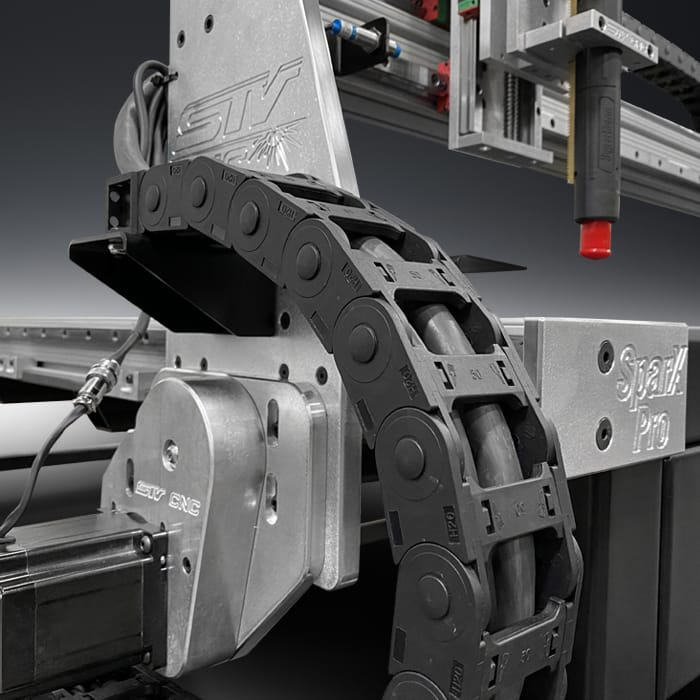

PRECISION MOTORS & TRACK

➤ Motor Enclosure: Open & Accessible – No Housing VIEW

➤ Z-Axis Linear Stepper Motor Positioner VIEW

➤ Durable Automation Wiring, Handcrafted & Labele VIEW

➤ Advanced Cable Management Upper Gantry & Lower Table Side Cable Tracks VIEW

➤ Motion Accuracy: 0.002” per 12″ inches

➤ Step Resolution: (+) or (-) 0.0005” inches

➤ Precision Margin of Error (10ft Travelled): 10 ft. = Off by 0.02″- 0.05″

➤ Attached Control Box with E-Stop VIEW

➤ Input Power: 110VAC for the Control Box. Your choice of Plasma Cutter will require 220-600VAC

➤ Controller Connectivity: USB (6ft. Cable Included)

➤ CNC Software & Controller

➤ File Types: .dxf, .plt, .tap, .2d, .hpgl

➤ CAD/Design: Inkscape & QCAD

Please Note: You may be required to purchase/source a 8′ foot earth grounding rod to prevent electrical interference (EMI).

Please Note: You may be required to source a Windows OS based laptop/desktop computer to install the Controller Software and any additional design software you may use in production.

CHOOSE STV®CNC & ALWAYS GET MORE

➤ Access to Table Owner’s Documents

➤ Software & Table Operation Tutorial Videos

➤ Library of 1000+ DXF Cut Files

➤ STV®CNC Manufacturer’s one year warranty

➤ Golden Prestige™ Lifetime Tech Support (See Support Section below.)

➤ Access to our Private Plasma Table Owner’s Facebook Community VIEW

➤ Access to shared files, skills and setting VIEW

➤ Network Nationwide and make new friends in your trade VIEW

➤ STV® Family Promo codes & Purchase access to Hypertherm® Consumables/Cartridges

➤ STV®CNC Purchase access to Plasma Guard STV®

➤ STV®CNC Purchase access to Table Replacement Parts

➤ STV®CNC dedicated tech support for software, product & table operation.

For Shop Preparation, this Recommended List shares helpful options to consider sourcing outside of your table purchase. For Any additional questions on the items below, you are always welcome to speak with our support staff at 1-888-701-7101

Equipment & Material Recommendations:

- Plasma Guard STV®: Anti-rust solution for your table, water pans, slats and cutting pieces. Read more

- Hypertherm® Consumables: These Consumables are for your Mechanized Torch in the cutting process VIEW.

- Plasma Cutter Power Setup: VOLTS: 200-600VAC, AMPS: 50 (Contact Plasma Manufacturer for Electrical Setup.)

- Computer/Control Box Power Setup: VOLTS: 110, AMPS: 20 (Contact a Professional & Certified Electrician for Electrical Setup.)

- Plasma Cutting System & Torch: Hypertherm® Powermax45®XP Plasma Cutting Unit or higher with a Mechanized Torch.

- Air Compressor: Source an Air Compressor with a Minimum of: Capable of 6 SCFM at 90 PSI.

- Air Dryer: Refrigerated Air Dryer or dessicant filter system that will match your compressor specs.

- Computer: For File Design & Storage. Minimum of 3 GHz Desktop Computer or Laptop, WindowsXP or newer with 16 GB RAM, 250 MB storage, 2 USB ports.

- Metal Supply: Source your nearest Metal Sheet Supplier in your area.

- Water Agitation: We recommend if one cuts a wide variety of materials in their plasma table, to install a water filtration system that agitates the water. Install an Aerator, Bubble Muffler or Water Filtration System for Surface Agitation, Oxygenation & Water bed Gas Dissipation. Clean any submerged, cumulative surface areas or Hydrogen gas trapped pockets of Aluminum particles in your water bed. (especially prevention against the mixing of aluminum particles with mild steel particles in your water bed.)

- Safety & Prevention: Dust Removal system, PPE: Eye & Ear Protection, PPE: Respirator, On-site Ventilation

Tools for Table & Assembly Recommendations:

- White Cable: The”White cable” in your crate items is your Ohmic Sensor for DRY CUT operations. For Non-Sync Hypertherm® Systems, you will be required to purchase Hypertherm® Consumable 220993 at www.stvcnc.com/hypertherm-consumable-hub

- Table Layout: We recommend a LEFT SIDE Installation. Cable Track, Table & Computer on Left Side. Consider the side you will be loading steel sheets onto the plasma table. Your Plasma Cutter requires a minimum of 6′ feet in distance from the computer and control box.

- Exposure: This is an INDOOR Plasma Table. Not recommended for outdoors or exposure to an outdoor environment. Maintain table & wipe linear guides down with WD-40 and scouring pads regularly.

- Interference: The crossing of cables may cause interference. Make sure that your TORCH CABLE does not touch the Z-Motor at the top of your Z-Axis Head. Make sure your USB CABLE does not cross signals as well.

- Grounding Rod: Install an 8′ foot Earth Grounding Rod to prevent interference. We recommend installing the earth grounding rod to avoid material waste & any possible mechanical ghost movements that interference may cause.

- Digital Caliper: Helps measure cut outs & metal sheets.

- Magnet Stick: Helps remove cut pieces/debris/tip-ups off of the table and/or water pans.

- PPE Gloves/Eye Protection: Work Gloves to help handle any cuts that may still be hot and transfer of metal sheets in production. Consider Eye protection from any debris or Plasma Cutting glare or sparks. Follow Safety Precautions in your Hypertherm® Safety Guide.

- Zip ties: help keep cables organized & prevent interference. Important: Make sure you UNCOIL your cables. This includes the excess of your Torch cable, the PC cable and Grounding Work Lead Clamp.

- Other tools for Assembly: Standard & Millimeter Allen hex key and wrench set, Hex Socket/Wrench Set, Hex Socket Drill, Level, Large Pliers, Rubber Mallet for slat installation, Tape Measure, 1/8″ inch tip flat screwdriver for cable track clips, Utility Safety Gloves/Latex Gloves and Two short wooden blocks of the same length to assist in gantry alignment.

Clean Time / Maintenance Recommendations:

Cleaning time is usually between 30 minutes to 3 hours, depending on what water pan coating you have chosen to apply. It may take longer if water pans are bare.

- How do Table Owners prep their water pans for easy cleaning? Many of our Table Owners have chosen to coat their water pans in different ways with: POR 15, & high temp (high aluminum) silver paint, Marine Grade Epoxy, Duralux Marine Primer & Paint, Powder Coating, Powder Coating with Anode rods, Ospho & copper-infused boat bottom paint, Water District 3M Powder Coat product, 1/8″ thick layer of Flex Seal.

- WD-40 & Scouring pads & Microfiber Towels: Assists in table maintenance and cleaning.

- Lithium Grease Blend (EP00 or EP000) & an Ares Grease Gun Kit: Assists in table maintenance for Carriage bearings.

- Water Pump: Assists in table maintenance and water removal.

- Green Light Checklist: We have prepared 8 key points to check at your site of production to ensure a successful cut. Visit the Green Light Checklist at www.stvcnc.com/greenlightchecklist

- Other tools for Cleaning: Tools many Table Owners have used: Needle Scaler, Scraper, Wire Wheel, Weed burner, Wet Sand Blasting, Shop Vacuum, evaporative cooler pump, Red Tip Pressure Washer.

➤ We also recommend one get the approval of their spouse. Sorry we don’t make the rules, they do.

PAYMENT

➤ TAXES: If you reside in the State of Nevada, you will be charged Nevada Sales Tax. Sales tax will not be added to orders if the purchaser resides outside of the State of Nevada.

➤ PAY BY PHONE: We can take a payment via phone. We’ll follow thru to provide you with a “paid in full receipt” and confirm the shipping address before sending the purchase order into production.

➤ PAY BY INVOICE: We can send you an interactive invoice of the items requested where you can tap on the “Pay Now” Tab to proceed with a Credit card, Venmo, Amazon Pay, PayPal or Wire transfer.

➤ REQUEST AN ESTIMATE: We can send you an estimate price quote prepared of the items requested.

➤ PAY ONLINE: There are products on our website that require lead time check and/or calculation of flatbed hotshot trucking distance to your location. A full online experience will not be possible, one will have to call 1-888-701-7101 to verify your order’s details.

➤ PAY VIA SCHOOL/GOVT/UTILITY: For Public Universities, Schools, Government agencies & Utilities, please provide your Purchase Order with Net30 Terms along with your vendor package.

➤ PAY VIA FINANCING: We also via third-party offer financing for your purchase. One can quickly apply for financing and be approved in as little as 3 minutes. Read more

All STV®CNC PRO Tables are shipped fully built to your location via Flatbed Hotshot Shipping (VIEW). The “Distance Cost & Handling” will need to be determined before full purchase, check with your Sales Agent at 1-888-701-7101 to complete your order’s details.

➤ OPTION 1: PICKUP. Dimensions: L:7′ x W:6′ x H:5′. Hou have the free option of picking up your item, available at our facility. Schedule with your Sales agent for Pickup Day/Time. For “Self Pickup” please have ready “TARPS & STRAPS” (VIEW) for securing and protecting your load against the elements. An ideal flatbed trailer “without fenders” will work. Any concerns on your trailer meeting requirements, please confirm with your sales agent for further details.

6160 N. Hollywood Blvd. #110, Las Vegas, Nevada, USA 89115 MAP ▶

➤ OPTION 2: SHIP. Weight: 1250 lbs. Call 1-888-701-7101 to Calculate Continental U.S. Shipping of Distance Cost & Handling. Check with your Sales Agent on this. Flatbed Hotshot Shipping (VIEW). A Forklift will be required at your location upon delivery for unloading. Excludes Hawaii, Alaska & Puerto Rico (see “Sea Freight” below).

SHIPPING QUESTIONS

➤ Are there any ADDITIONAL SHIPPING COSTS?

Any of the next 5 scenarios may apply in the shipping of your item.

01. COMMERCIAL DELIVERY: Check with your Sales Agent for your order’s shipping details.

02. LIMITED ACCESS: Check with your Sales Agent for your order’s shipping details.

03. RESIDENTIAL DELIVERY: Check with your Sales Agent for your order’s shipping details.

04. LIFTGATE: Check with your Sales Agent for your order’s shipping details.

05. SEA FREIGHT – For International orders, you will need to cover U.S. Ground Shipping from Las Vegas to the Port of your choice. After that, you will need to organize your choice of Sea Freight to pick up at that port and have it shipped to your location. If you have a moment, search for Sea Freights to your location and inform us with the Port location we will be shipping to within the U.S. and we can go from there.

➤ What happens at DROP OFF?

The Flatbed Hotshot Shipping (VIEW) will deliver your table to the location you provided. Please advise your STV®CNC Sales Representative with any delays, gate codes, special entry requirements or deadlines that might hinder or prevent delivery attempts. Please check the table before Delivery is completed to ensure no damages were incurred during transportation. Please make sure you have a forklift and two (2) long 4×4 long wooden beams to side-unload your table from the delivery flatbed truck.

➤ How do you SHIP your PRO plasma tables?

We have a couple different ground Flatbed Hotshot Shipping (VIEW) carriers. The shipped plasma table ships with straps and tarps to protect it against the elements during transportation. Pickup at our Facility is also an available option.

➤ Do you ship to Canada, Dubai, Hawaii, Mexico or International?

To an extent; For International orders or locations out of the Continental United States, you will need to cover U.S. Ground Shipping from Las Vegas to the Port or Terminal of your choice. After that, you will need to organize your choice of Ground or Sea Container Freight to pick up at that port and have it shipped to your location. If you have a moment, search for sea freight carriers to your location and inform us with the Port location we will be shipping to within the U.S. and we can go from there. You will be required to delegate the international brokerage and fees.

➤ Can I pick up my PRO Table at the Terminal?

Potentially, depending on your location and whether or not you have a truck or trailer able to pull 1250 to 2100 lbs. of weight (depending on the PRO table size you purchased.) Check with your sales agent for trailer fitting.

➤ FACTORY-DIRECT. We pride ourselves in managing and organizing the output of CNC Tables as they roll off our Factory Production Line. Get your order in to be queued up for Production and Delivery today. Up to date lead times are available by calling your STV® Sales Agent at 1-888-701-7101.

SUPPORT

Backed by our Golden Prestige℠ Tech Support

Your New Modular Production Table is backed by our Golden Prestige℠ Technical Support that offers solutions across a wide range of customer support methods like Software & Table Operation Troubleshooting, Live Support via remote assistance, as well as Hypertherm® Unit Troubleshooting well before any escalation occurs and enjoying the ease of having us delegate any replacement parts to prevent any extended amounts of down-time.

Table & Software Dedicated Live Support

Our STV® Team Members are knowledgeable in troubleshooting topics on Table Operation, maintenance & software during business hours. We love to dedicate our full attention to troubleshooting. You can fill out the Support Ticket at www.stvcnc.com/support and we’ll contact you directly with the solutions to meet your needs. We’re available via phone with Tech Agents on queue, feel free to call 1-888-701-7101. You also will have additional support via our Private Nationwide Facebook Community.

Nationwide After Hours Active Networking Community

We currently have over 2,000+ savy and successful Plasma Table Owners who spread across various industries. The Facebook Private Community is healthy, positive and always forward moving for improvement & growth.

Troubleshooting Step-by-step Instructional Videos

We want to make sure we speed up you and your team’s learning curve. We’ve made sure to produce helpful step-by-step tutorial video sessions to make that happen. More than happy to continue troubleshooting after.

Source for Stocked Replacement Parts & Hypertherm® Product Support

STV®CNC is a proud OEM Distributor for all Hypertherm® products, including Plasma Cutting Units, consumables, cartridges & accessories. We also provide tech support for Hypertherm® products before escalation.

Fabrication Guidance in CNC and Shop

Our STV® Team Members are knowledgeable with industrial guidance for table operation protocols at your shop.

Support for Learning Curve Improvements in becoming Table & Software Proficient

Time is essential in getting you up and running on the basics for table operation, software and daily tasks. After watching our tutorial videos, we are here for any one-on-one phone calls or remote assistance where all support ends with solutions.

Full Support For Preventive Down-time, Table Maintenance, Operation & Software

Issues happen & we’re here for you. Within your warranty, we can quickly ship out components that may have failed over extensive wear & tear. Our table components are always in-stock and affordable even after your warranty has expired.

Troubleshooting Topic? Please contact Tech Support at www.stvcnc.com/support

ADD-ONS

These STV®CNC add-ons are additional accessories that one can customize and upgrade their table. Clicking on the accordion buttons below you will see product image, description and additional assisting documents that apply.

Plasma Guard STV® (Anti-Rust Solution)

Recommended if you would like to decrease production dust/debris, preserve your water pans & avoid any oxidation. The Blue Anti-Rust Solution will be sent to you in a 5 Gallon Bucket with an Instruction Label to follow upon use. Think you may need a second bucket? For Plasma Guard STV® Dilution Rates: Click here to read more about Plasma Guard STV®

Plasma Table Size | Add Plasma Guard STV® | Add Water |

2′ (L) x 4′ (W) Plasma Table | 1.1 Gallons (169 oz.) | + Add Reverse Osmosis Water up to operating level |

4′ (W) x 4′ (L) Plasma Table | 2.2 Gallons (338 oz.) | + Add Reverse Osmosis Water up to operating level |

5′ (W) x 5′ (L) Plasma Table | 3.5 Gallons (538 oz.) | + Add Reverse Osmosis Water up to operating level |

4′ (W) x 8′ (L) Plasma Table | 4.3 Gallons (661 oz.) | + Add Reverse Osmosis Water up to operating level |

5′ (W) x 10′ (L) Plasma Table | 7 Gallons (1076 oz.) | + Add Reverse Osmosis Water up to operating level |

6′ (W) x 12′ (L) Plasma Table | 8.5 Gallons (1306 oz.) | + Add Reverse Osmosis Water up to operating level |

*IMPORTANT: Numbers above reflect and apply to the amount of Plasma Guard STV® and water needed to pour into STV®CNC water pans for a recommended dilution ratio volume calculated at 3″ inches in depth. FOR BEST RESULTS, we recommend using REVERSE OSMOSIS (RO) WATER, but Plasma Guard STV® can be used in all water types if RO water is not available.

Windows Laptop with Software

New Windows 10 Laptop with Pre-installed MyPlasm CNC Controller program. This Brand New Windows 10 Laptop is dedicated for “function” and will arrive with Installed Software, Setup and USB Connectivity. The term “Function” refers to the primary use of sending files directly to cut onto the table from this device. This “Send to Cut Laptop” device may not be capable of processing heavy Design/CAD programs like AutoCAD, Fusion360, etc. For “Designing Cut Files” and “file storage/management”, we recommend sourcing a laptop or desktop with gaming processing power. Laptop Make and Model may differ upon availability.

(Important: This Windows Laptop PC is only for MyPlasm CNC Software and it is “NOT” to be confused with the Linux MiniPC offered with the Optimum CNC Controller.)

STV®CNC Rollerballs

These transfer bearings are ideal for individual loading material efficiently. Recommended to protect the table and offer the additional ease of loading or shifting steel sheets onto your production table. These material support ball transfers are durable and practical, made of steel and rotate 360°degrees.

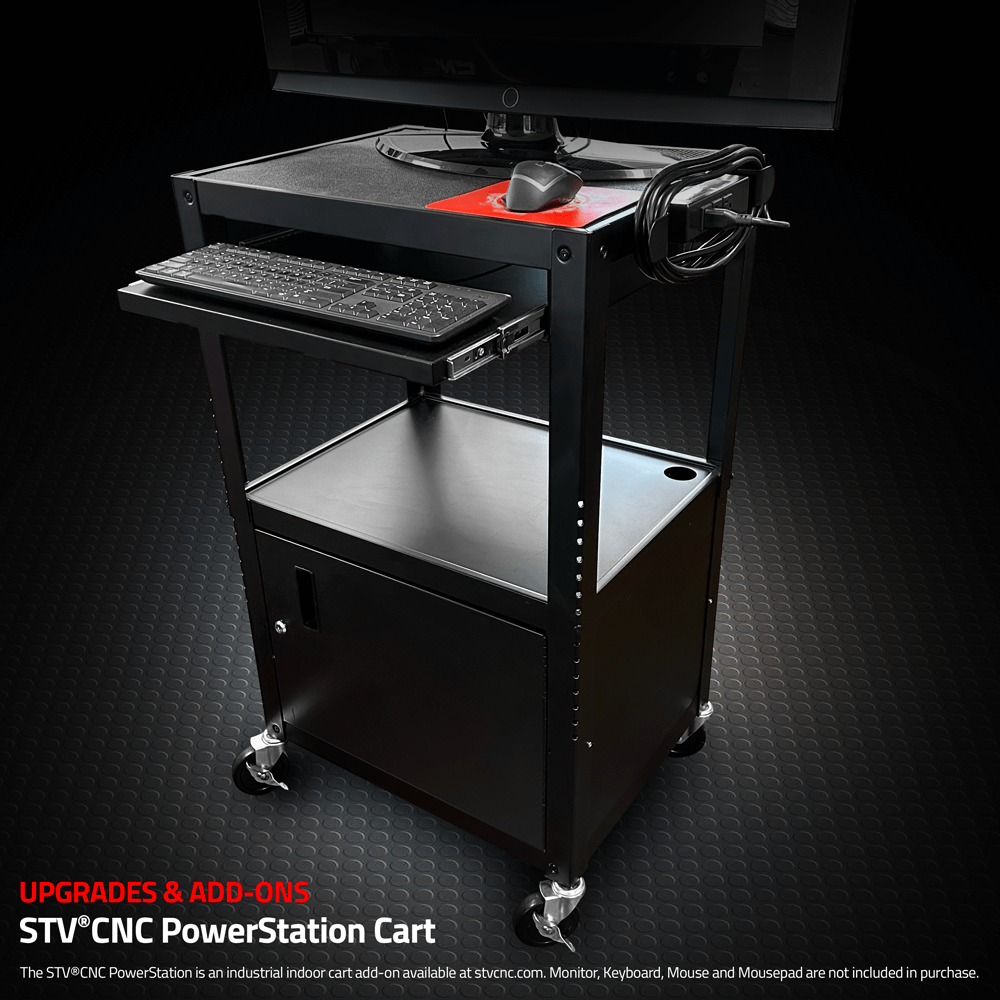

PowerStation Cart

Click here to READ MORE. 42″ inch Mobile Workstation Cart. Maximize your workspace with this Double Shelf PC standing desk as its adjustable height improves production house mobility. Includes 15′ ft. Triple Outlet Power Strip, Cabinet w/ Lock, Gliding Tray & Locking Caster Wheels. Recommended Indoor Use Only. ASSEMBLY REQUIRED.

( 19.5″L x 24.875″W x 42″H )

BOOK A TOUR OF STV®CNC

Las Vegas is home to our STV®CNC family of dedicated staff members. We would love to have you see our 50,000 sq. ft. Headquarter Operations. CLICK HERE TO BOOK A TOUR.

HYPERTHERM®

We are proud to be an Official OEM Distributor for Hypertherm® Systems, consumables, cartridges & accessories. Clicking on the accordion buttons below you will see product image, description and additional links that apply. See the Plasma Power Comparison Chart.

Hypertherm® Powermax 45XP Plasma Cutting System

6,525 WATTS OF PLASMA POWER !

Power Rating: 45 Amps (A) x 145 Volts (VDC) = 6,525 Watts (W)

1/2” INCH PIERCE. Meet the newest member of the best-selling line of Powermax® portable plasma systems. The Powermax45® XP plasma cutter delivers increased cut capacity – up to 5/8″ inch (16 mm) metal – as well as faster cut speeds, and automatic gas adjustment for quick, simple setup and operation.

Hypertherm® Purchase includes: Plasma System, STV®CNC CPC cable ($200 value), work clamp, set of standard consumables & a 25ft. mechanized torch. IMPORTANT: Depending on the model you select, Plasma Cutting System lead times fall into a queue list for each model series as we receive them from Hypertherm® and out to you. In 100% transparency, we strive to deliver a well-rounded experience. Feel free to call us to chat about lead times. 1-888-701-7101

Hypertherm® Powermax 65 SYNC® Plasma Cutting System

9,035 WATTS OF PLASMA POWER !

Power Rating: 65 Amps (A) x 139 Volts (VDC) = 9,035 Watts (W)

5/8” INCH PIERCE. The Powermax65 SYNC® is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for cutting and gouging up to 20 mm (3/4″). Featuring automated system process set-up via advanced RFID-enabled SmartSYNC™ torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax65 SYNC® maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

Hypertherm® Purchase includes: Plasma System, 25’ft. SmartSYNC™ torch, 25’ft. Clamp, STV®CNC CPC Cable, (3) SmartSYNC™ Cartridges, (3) Ohmic rings, Cut Chart Manual, Instructional USB, (3) year unit warranty and a (1) year torch warranty. IMPORTANT: Depending on the model you select, Plasma Cutting System lead times fall into a queue list for each model series as we receive them from Hypertherm® and out to you. In 100% transparency, we strive to deliver a well-rounded experience. Feel free to call us to chat about lead times. 1-888-701-7101

Hypertherm® Powermax 85 SYNC® Plasma Cutting System

12,155 WATTS OF PLASMA POWER !

Power Rating: 85 Amps (A) x 143 Volts (VDC) = 12,155 Watts (W)

3/4” INCH PIERCE. The Powermax85 SYNC® is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for cutting and gouging up to 25 mm (1″). Featuring automated system process set-up via advanced RFID-enabled SmartSYNC™ torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax85 SYNC® maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

Hypertherm® Purchase includes: Plasma System, 25’ft. SmartSYNC™ torch, 25’ft. Clamp, STV®CNC CPC Cable, (3) SmartSYNC™ Cartridges, (3) Ohmic rings, Cut Chart Manual, Instructional USB, (3) year unit warranty and a (1) year torch warranty. IMPORTANT: Depending on the model you select, Plasma Cutting System lead times fall into a queue list for each model series as we receive them from Hypertherm® and out to you. In 100% transparency, we strive to deliver a well-rounded experience. Feel free to call us to chat about lead times. 1-888-701-7101

Hypertherm® Powermax 105 SYNC® Plasma Cutting System

16,800 WATTS OF PLASMA POWER !

Power Rating: 105 Amps (A) x 160 Volts (VDC) = 16,800 Watts (W)

7/8” INCH PIERCE. The Powermax105 SYNC® is a next-generation professional grade air plasma cutter that dramatically simplifies system operation for cutting and gouging up to 32 mm (1-1/4″). Featuring automated system process set-up via advanced RFID-enabled SmartSYNC™ torches and a revolutionary single-piece cartridge consumable that provides trackable utilization data. The Powermax105 SYNC® maximizes productivity through reductions in downtime, optimized cut quality performance and streamlined consumable inventory management.

Hypertherm® Purchase includes: Plasma System, 25’ft. SmartSYNC™ torch, 25’ft. Clamp, STV®CNC CPC Cable, (3) SmartSYNC™ Cartridges, (3) Ohmic rings, Cut Chart Manual, Instructional USB, (3) year unit warranty and a (1) year torch warranty. IMPORTANT: Depending on the model you select, Plasma Cutting System lead times fall into a queue list for each model series as we receive them from Hypertherm® and out to you. In 100% transparency, we strive to deliver a well-rounded experience. Feel free to call us to chat about lead times. 1-888-701-7101

Hypertherm® Powermax 125® Plasma Cutting System

21,875 WATTS OF PLASMA POWER !

Power Rating: 125 Amps (A) x 175 Volts (VDC) = 21,875 Watts (W)

1” INCH PIERCE. Delivering maximum power and performance for air plasma, the Powermax125® plasma system cuts thick metals fast. Able to make short work of the toughest cutting and gouging jobs, the system offers a 100% duty cycle, a 1″ inch (25 mm) mechanized pierce capability, and fast gouging metal removal. It also gives you the latest technological innovations, such as Smart Sense™ technology to automatically adjust the gas pressure. Eleven Duramax® Hyamp™ torch styles provide versatility for hand cutting, portable automation, X-Y table cutting, extended reach cutting, and robotic cutting and gouging.

Hypertherm® Purchase includes: Plasma System, STV®CNC CPC cable ($200 value), work clamp, set of standard consumables & a 25ft. mechanized torch. IMPORTANT: Depending on the model you select, Plasma Cutting System lead times fall into a queue list for each model series as we receive them from Hypertherm® and out to you. In 100% transparency, we strive to deliver a well-rounded experience. Feel free to call us to chat about lead times. 1-888-701-7101

ADAPTERS

Adapters are a list of Cables, Hand Torches or Mechanized Torches if you already own a Hypertherm® Plasma Cutting System or if you require an “additional” Hypertherm® Accessory for the purchase of a new plasma system. If you are purchasing a New Plasma System, it already includes the necessary Mechanized Torch & STV®CNC CPC Cable that applies along with the unit.

STV®CNC CPC Interface Cable

Select “ONLY” if you are an existing Hypertherm® Plasma System Owner & require a CPC cable. If you purchase a Plasma Table with us & decide to use your personal plasma system or decide to purchase one elsewhere, you will need to purchase this item to connect your plasma system to the STV®CNC Control Box.

Hypertherm® Non-SYNC Mechanized Torch

Select “ONLY” if you already own a Hypertherm® Plasma System & require a Mechanized Torch to install into the Plasma Table. This Hypertherm® torch is 25 feet in length. Please contact us if you desire a longer length of torch. If you are purchasing a New Hypertherm® Plasma Cutting System, it already includes the necessary Mechanized Torch that applies along with the STV®CNC CPC Cable.

This Torch Applies to:

Powermax 45®XP

Powermax65® Non-SYNC

Powermax85® Non-SYNC

Powermax105® Non-SYNC

Hypertherm® SYNC Mechanized Torch

Select “ONLY” if you already own a Hypertherm® SYNC Plasma System & require a Mechanized Torch to install into the Plasma Table. This Hypertherm® SYNC torch is 25 feet in length. Please contact us if you desire a longer length of torch. If you are purchasing a New Hypertherm® SYNC Plasma Cutting System, it already includes the necessary Mechanized Torch that applies along with the STV®CNC CPC Cable.

This Torch Applies to:

Powermax65® SYNC

Powermax85® SYNC

Powermax105® SYNC

Hypertherm® HYAMP Mechanized Torch

Select “ONLY” if you already own a Hypertherm® 125 HYAMP Plasma System & require a Mechanized Torch to install into the Plasma Table. This Hypertherm® HYAMP torch is 25 feet in length. Please contact us if you desire a longer length of torch. If you are purchasing a New Hypertherm® 125 Plasma Cutting System, it already includes the necessary Mechanized Torch that applies along with the STV®CNC CPC Cable.

This Torch Applies to:

Powermax125® HYAMP

Hypertherm® Non-SYNC Hand Torch

Select “ONLY” if you already own a Hypertherm® Plasma System & require an additional Hand Torch. This Hypertherm® hand torch is 25 feet in length. Please contact us if you desire a longer length of torch. The 25 foot Duramax® 75° hand torch is well suited for a variety of applications such as gouging, fine feature cutting, extended reach cutting, and flush cutting. The ergonomic design of the 75° torch is perfect for normal cutting.

If you are purchasing a New Hypertherm® Plasma Cutting System, it includes a MECHANIZED TORCH that applies along with the STV®CNC CPC Cable.

This Torch Applies to:

Powermax 45®XP

Powermax65® Non-SYNC

Powermax85® Non-SYNC

Powermax105® Non-SYNC

Hypertherm® SYNC Hand Torch

Select “ONLY” if you already own a Hypertherm® Plasma System & require an additional Hand Torch. This Hypertherm® hand torch is 25 feet in length. Please contact us if you desire a longer length of torch. The 25 foot Duramax® 75° hand torch is well suited for a variety of applications such as gouging, fine feature cutting, extended reach cutting, and flush cutting. The ergonomic design of the 75° torch is perfect for normal cutting.

If you are purchasing a New Hypertherm® Plasma Cutting System, it includes a MECHANIZED TORCH that applies along with the STV®CNC CPC Cable.

This Torch Applies to:

Powermax65® SYNC

Powermax85® SYNC

Powermax105® SYNC

Hypertherm® HYAMP Hand Torch

Select “ONLY” if you already own a Hypertherm® 125 HYAMP Plasma System & require a Mechanized Torch to install into the Plasma Table. This Hypertherm® HYAMP hand torch is 25 feet in length. Please contact us if you desire a longer length of torch. The 25 foot Duramax® 75° hand torch is well suited for a variety of applications such as gouging, fine feature cutting, extended reach cutting, and flush cutting. The ergonomic design of the 75° torch is perfect for normal cutting.

If you are purchasing a New Hypertherm® 125 Plasma Cutting System, it already includes the necessary Mechanized Torch that applies along with the STV®CNC CPC Cable.

This Torch Applies to:

Powermax125® HYAMP

FINANCING

Five Reasons to Finance your next purchase.

-

Get your equipment when you need it.

With financing, you can get the equipment you need now — and avoid making a hefty payment all at once.

-

Know what you’re paying each month.

You'll have a predictable monthly payment, which can help you plan for the future and budget for your other business needs.

-

Financing is simple — and quick.

With our simple online application that you can complete in minutes, you could get quick turnarounds on approvals.

-

Keep your cash reserves available.

Paying for your equipment over time means you can avoid tying up your cash all at once.

-

Reap potential tax benefits.

Financed equipment could be deducted as an operating expense in the period in which it’s paid and put into use — and that could reduce your overall cost. Payments are also treated as expenses on the income sheet, so there’s no need to worry about depreciation.

© 2023 First-Citizens Bank & Trust Company. All rights reserved. First Citizens Bank is a registered trademark of First Citizens BancShares, Inc. Not all applicants will qualify for financing. All finance programs and rates are subject to final approval by First-Citizens Bank & Trust Company, and are subject to change at any time without notice. Speed and performance are subject to applicant’s local connectivity and other factors outside First-Citizens Bank & Trust Company’s control. Supporting financial documentation may be required for any transaction with First-Citizens Bank & Trust Company. If a transaction is over $250k, then supporting financial documentation will be required. This is not intended to offer any tax advice or other advice. Applicants should consult with their tax advisors concerning their specific tax situations. Member FDIC. MM#12935

Financial Assistance for your STV®CNC Order is available through First Citizens Bank or through an assorted list of top financing lenders. Quicken Equipment Ownership with flexible terms that work best for your operation.

STV®CNC offers financial assisting options through First Citizens Bank or through an assorted list of available top lenders who offer different tiers of financing. Finance essential CNC equipment, Plasma Tables or Router Tables for your business. Expand your financing options. Get the resources you need to make your business flourish with an exceptional financial backing with options that work best for you. With experience working with small businesses we know what it takes to start, expand and have the correct measures that will support your daily operations along with any flexible small business loans and financing solutions to meet your needs.

General Information about our In-house built CNC Plasma tables.

Get a high-end, fully-welded and assembled 4×4 CNC plasma table for your business at a price that makes sense.

- Industrial-grade level CNC plasma table for small to large sized industrial and fabrication markets.

- Professional plasma table that uses high-end machine features and capabilities.

- Included water table helps to reduce dust and metal warping.

Are you looking for a new CNC plasma table for your business? Then the STV®CNC SparX™ Welded Pro 4 Plasma Table is just what you need. This industrial level CNC plasma table is perfect for companies just getting started with CNC machining or for those looking to increase production capabilities. With several advanced attachments like a water table that helps prevent dust and metal warping from the high levels of heat and the included automatic torch height control, you’ll be able to create amazing metal designs. With high-end components, this plasma table delivers some of the best plasma cutting speeds and consistency around. Get your 4 x 4 automated plasma table today!

- Uses Windows OS interface

- Several advanced attachments included

- Dry or water pan options available

- Automatic torch height control included

We have applied the best technologies of high-end, industrial level CNC plasma tables at a competitive price. The STV®CNC SparX™ Pro Plasma Table Series incorporates high-end machine features and capabilities, in a simple but effective package. Using our high accuracy stepper motors for speed, control and smooth operation and combining it with ground linear bearings and guide rails results in consistency and speed that is unrivaled in the industry. Additionally, our tables are built tough and designed to easily handle inch thick steel plates and they can handle much more. Proudly made in the USA.

STV®CNC Reviews –

➤ Click here to Read Reviews & Comments.